Aluminum Oxide (Al₂O₃)

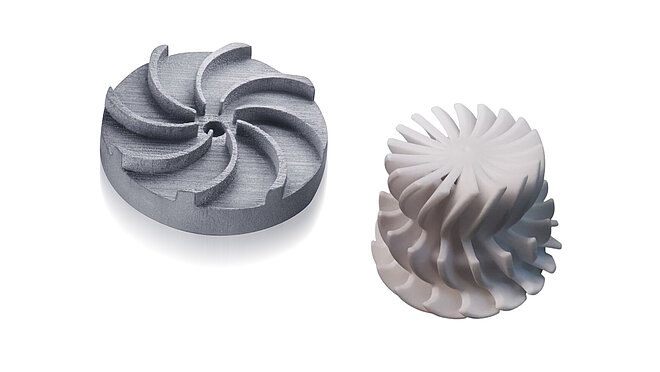

Aluminium oxide (Al2O3) in its various degrees of purity is the most frequently used high-performance ceramic material.CeramTec has a whole range of material types with different property profiles, which are adjusted through targeted microstructure design.Both coarse-grained and fine-grained variants are available.

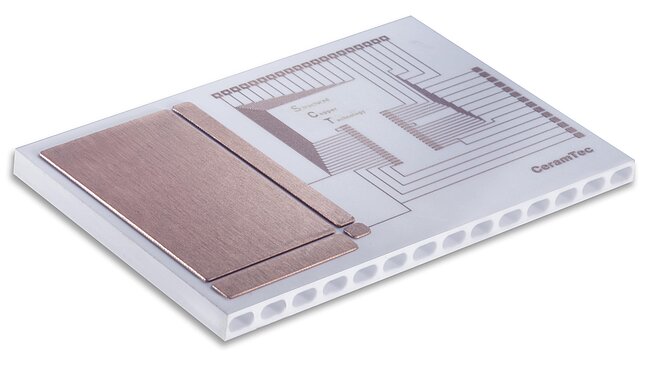

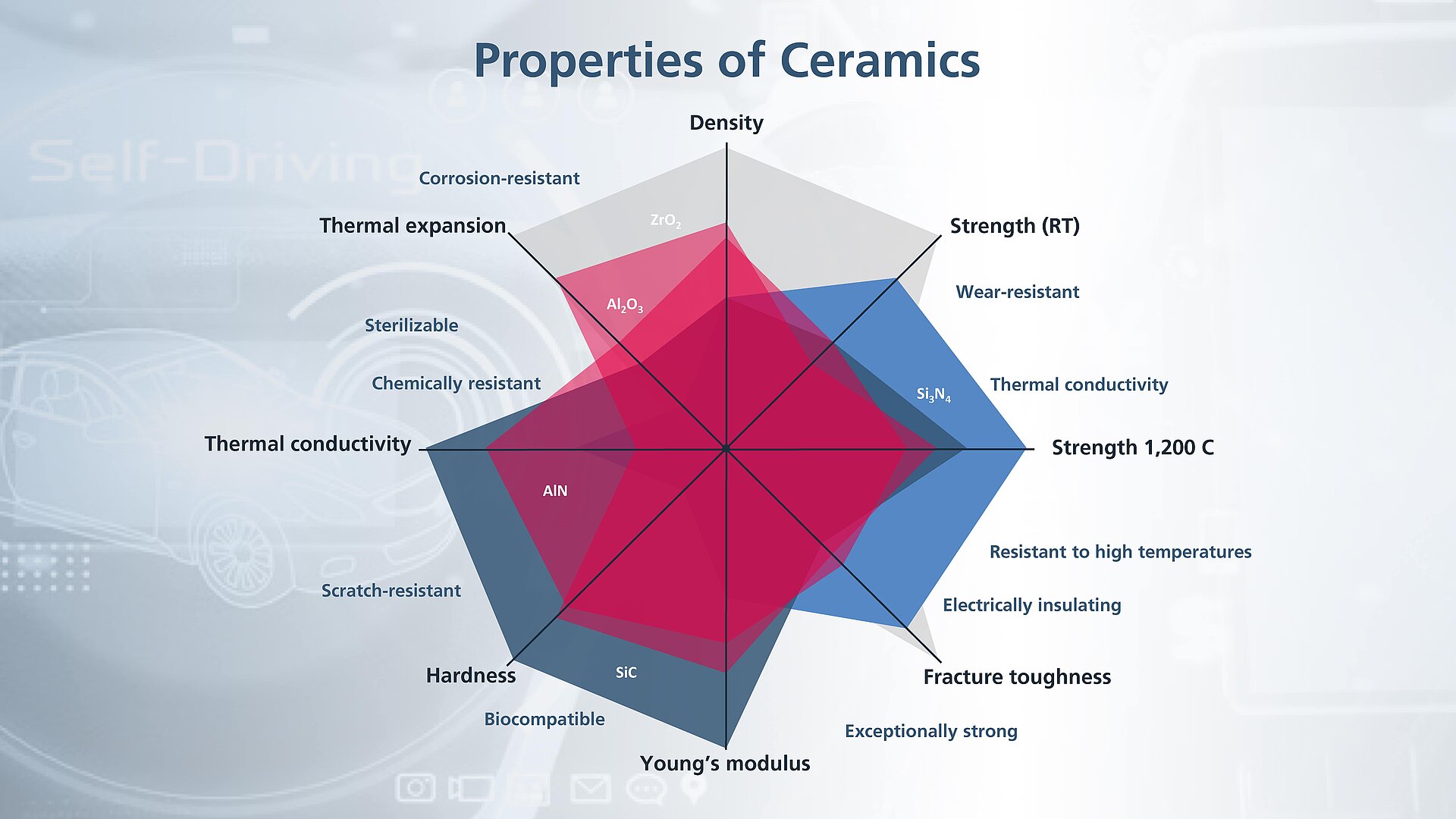

Aluminium oxide (Al₂O₃) is characterised by high hardness, thermal stability and exceptional corrosion resistance. Due to its high electrical insulation capacity and thermal conductivity, it is often used in electronics, particularly for substrates and insulating materials. In medical technology, it is used as an implant material due to its biocompatibility and wear resistance. Aluminium oxide also plays an important role in future technologies such as semiconductor production and energy storage, for example as a protective layer in batteries. Another speciality is its resistance to chemical attack and its use as an abrasive due to its hardness.

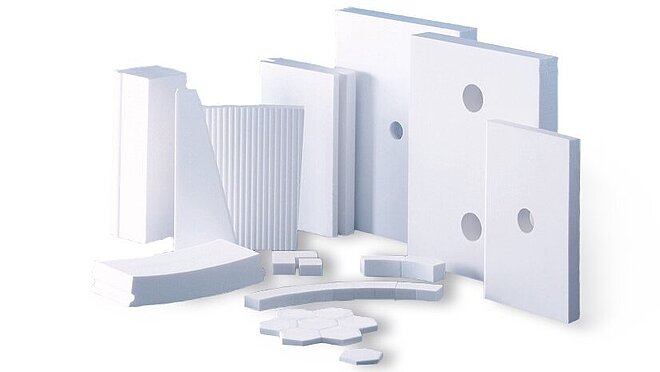

CeramTec Areas of Application

- Heavy-duty forming tools

- Substrates and resistor cores in the electronics industry

- Tiles for wear protection

- Thread guides in textile engineering

- Seal and regulator discs for water taps and valves

- Heat-sinks

- Protection tubes in thermal processes

- Catalyst carriers for the chemicals industry

Properties of Alumina/Aluminum Oxide (Al₂O₃)

- Very good electrical insulation (1x1014 to 1x1015 Ωcm)

- Moderate to extremely high mechanical strength (300 to 630 MPa)

- Very high compressive strength (2,000 to 4,000 MPa)

- High hardness (15 to 19 GPa)

- Moderate thermal conductivity (20 to 30 W/mK)

- High corrosion and wear resistance

- Good gliding properties

- Low density (3.75 to 3.95 g/cm3)

- Operating temperature without mechanical load 1,000 to 1,500°C.

- Bioinert and food compatible