Ceramic Substrates

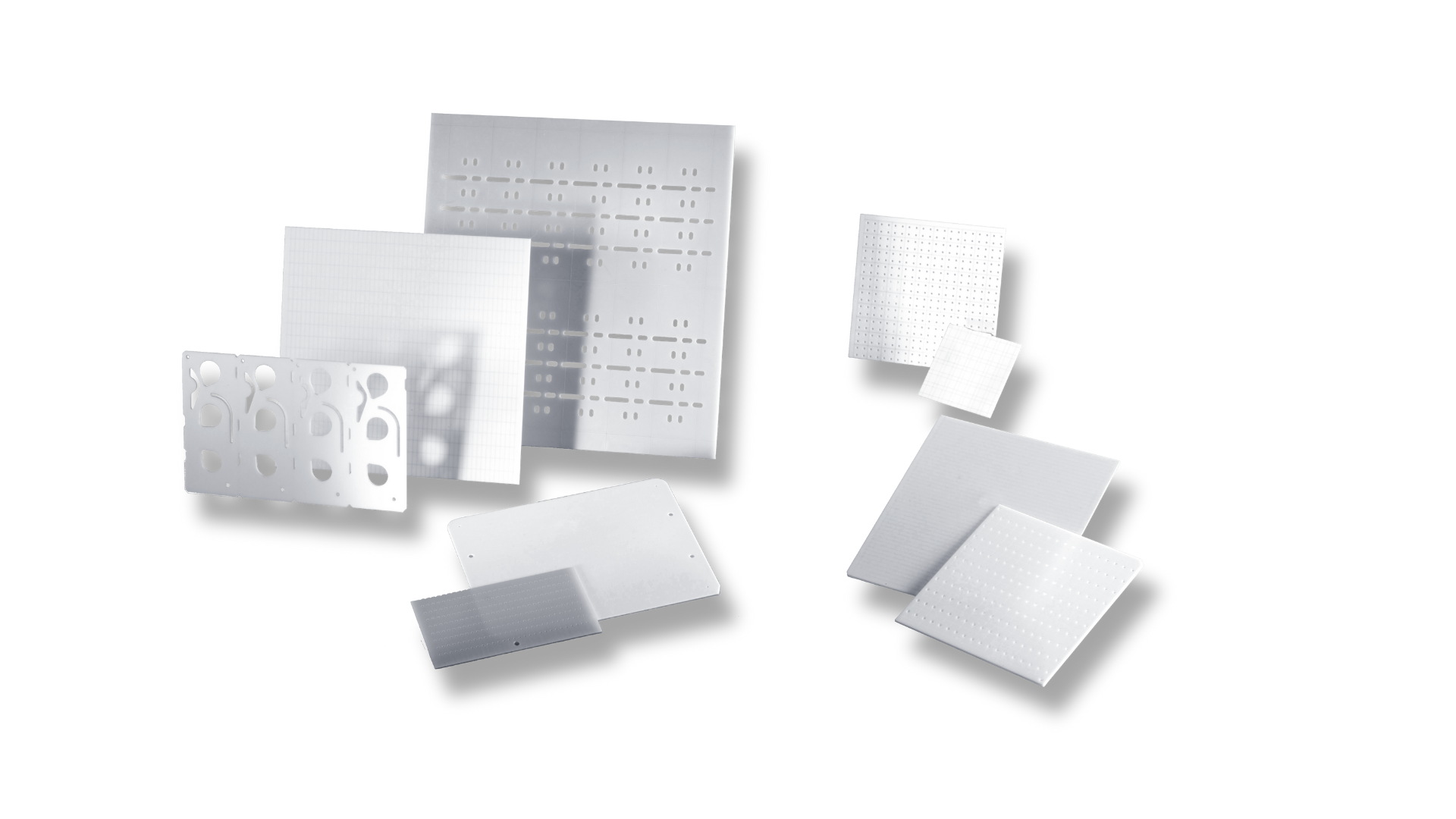

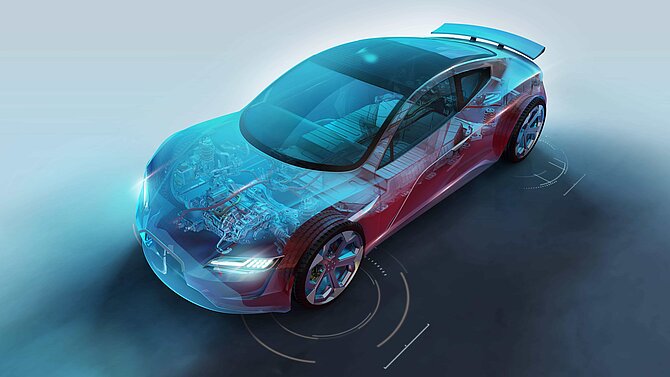

How do modern electronic systems manage to function reliably even under extreme conditions? Which materials enable efficient control of high power densities? With its ceramic substrates made of aluminium oxide, aluminium nitride, zirconium oxide-reinforced aluminium oxide (ZTA) and silicon nitride, CeramTec provides tailor-made solutions for demanding applications. They are characterised by outstanding thermal conductivity, mechanical strength and electrical insulation properties. This makes them indispensable for industries such as medical technology, telecommunications, electromobility and energy generation. Discover how CeramTec can take your electronic applications to the next level.

CeramTec is your One-Stop-Shop for all common ceramic substrates and offers everything from a single source: aluminium oxide, aluminium nitride (with a bending strength of 450 Mpa), zirconia toughened alumina ZTA, zirconium oxide ZrO2 and since spring 2024 also silicon nitride.

In addition to the ceramic substrates, this also includes engineering as well as laser processing and metallization of the substrates. The comprehensive one-stop-shop portfolio of ceramic materials enables our customers to source all major ceramic substrates from a single European manufacturer, supplement them as needed and streamline their supply chains.

Our ceramic substrates are characterised by a high packing density in terms of size and weight, which is achieved through their excellent ampacity, thermal conductivity and efficient heat spread with a thick copper metallisation by the customer.

At the same time, the low specific weight is maintained due to the low bulk density of the ceramic compared to, for example, metal. This makes our ceramic substrates the optimal choice for demanding applications where efficiency and performance are paramount.

Outstanding thermal conductivity of our ceramic materials, such as aluminium nitride (AlN), aluminium oxide (Al2O3), zirconium oxide-aluminium oxide (ZTA) and silicon nitride (Si3N4).

Thanks to the extraordinary lattice vibrations in ceramics (phonon resonance), they achieve remarkable heat dissipation compared to plastics. These properties make ceramics a first-class choice for heat-sensitive applications.

The excellent suitability for use in the high frequency range is ensured by a low dielectric loss factor or tan delta of the ceramic materials. A low dielectric loss factor is essential to ensure that the material has minimal energy loss and low attenuation effects on high frequency signals. This leads to improved efficiency and performance of high frequency components and systems.

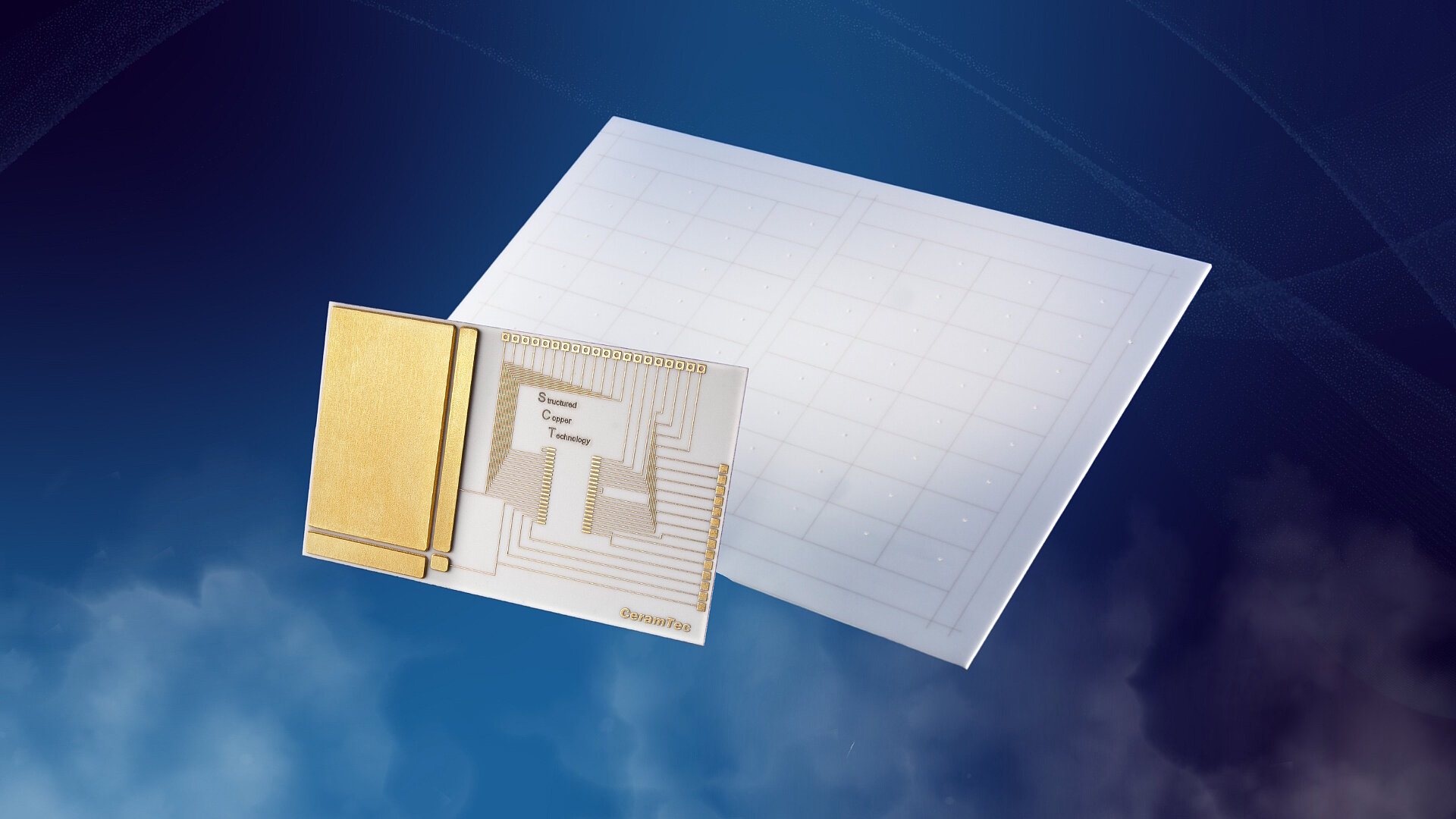

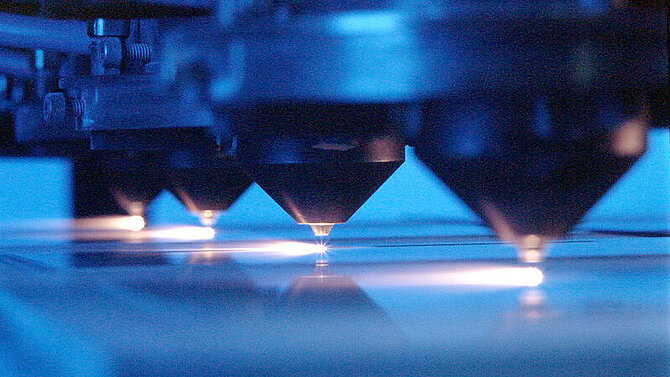

Lasered and Metallised Substrates

At CeramTec, we manufacture and process ceramic substrates using various processes depending on the application, material, geometry and number of pieces: From punching, lasering and dry pressing to various hard machining processes.

In addition, we also metallise the substrates ourselves, making them ideal for direct assembly with electronic components. The metallisation pastes are developed by ourselves and are characterised by high adhesive strength, good solder flow and excellent resistance in solder baths. In the process, a conductive layer is applied to the substrate to create the conductor paths and connections for the electronic components and to protect the substrate from corrosion or other environmental influences.

RoHS Certification

A key prerequisite for CeramTec’s successful partnership with the electronics industry is the ability to deliver the right materials.

CeramTec offers the world’s top ceramic materials for thick and thin film technology and provides ceramics optimally designed to meet your specification profiles.

FAQ - CeramTec Substrates

What materials does CeramTec offer for ceramic substrates?

CeramTec produces substrates made of aluminium oxide (Al₂O₃), aluminium oxide reinforced with zirconium oxide (ZTA), aluminium nitride (AlN) and silicon nitride (Si₃N₄). These offer excellent thermal conductivity, electrical insulation, chemical and mechanical stability and a long service life.

What is the difference between Al₂O₃, AlN and Si₃N₄ substrates?

Al₂O₃ is cost-efficient and offers good insulating properties, AlN impresses with excellent thermal conductivity, while Si₃N₄ offers maximum mechanical robustness combined with good thermal conductivity and insulation - ideal for operating conditions such as in e-mobility.

For which applications are ceramic substrates particularly suitable?

Ceramic substrates are used in e-mobility, renewable energies, industrial drives, railway and aviation technology and power electronics, among others. Wherever compact, reliable and thermally stable solutions are required.

How do CeramTec substrates support power electronics?

Substrates such as aluminium nitride dissipate heat efficiently, which is crucial for high-performance applications in power electronics. They ensure the reliability and durability of components. Substrates made of silicon nitride are ideal for e-mobility, as they are extremely break-resistant despite their minimal thickness, carry high current and heat loads, offer maximum electrical insulation and therefore enable compact, powerful and reliable power modules.

Can ceramic substrates from CeramTec be customised?

Yes, CeramTec offers customised substrates in various thicknesses, sizes and surface finishes. This enables optimum customisation to specific customer requirements. CeramTec also develops substrates whose properties and material compositions are customised to the respective customer requirements.

What advantages do CeramTec substrates offer in electronics?

The substrates offer high dielectric strength, thermal stability and resistance to environmental influences. They are ideal for compact, reliable power modules in demanding applications.

How does CeramTec contribute to miniaturisation in electronics?

Through precise manufacturing and thin, high-strength substrates, CeramTec supports the development of compact, efficient electronic components. This is particularly advantageous in microelectronics and sensor technology.

Which metallisation technologies are compatible with CeramTec substrates?

CeramTec substrates are compatible with AMB (Active Metal Brazing) and DCB (Direct Copper Bonding) as well as Sputter Metal Bonding (SMB) - depending on the material and application.