SPK® Cutting Tools

How can you get the most out of your machining processes, even with the most demanding materials? With SPK® by CeramTec, we combine over 70 years of experience with innovative cutting materials such as ceramics, CBN and whisker-reinforced ceramics to take your manufacturing to a new level. Whether cast iron, hardened steels or heat-resistant superalloys (HRSA) – our solutions stand for maximum productivity and process reliability. Together with you, we develop tailor-made tool systems that will impress not only today, but also tomorrow.

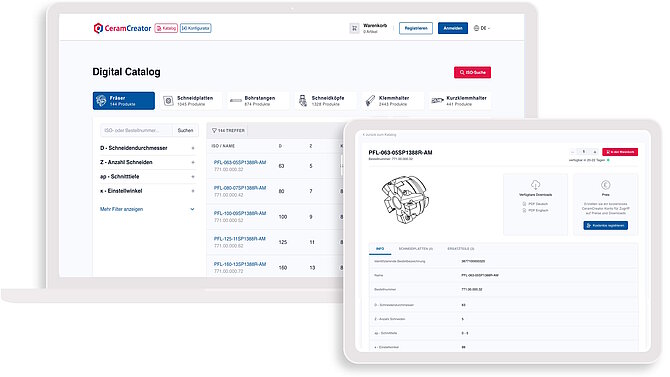

In summer 2024, we revived our traditional brand under the name “SPK by CeramTec” and expanded our range of machining solutions at the same time. Find out more about the comeback of SPK®.

Milling of HRSA Materials with Ceramic End Mills

Machining heat-resistant superalloys places high demands on tools, as heat, chip breaking and wear cause extreme stress on the tool cutting edge and place high demands on the cutting material. Our new white paper shows practical strategies for overcoming the challenges of milling Inconel & Co with ceramic end mills.

SPK® by CeramTec

CeramTec now operates its machining activities under the name SPK by CeramTec. With the revival of the traditional SPK brand, CeramTec is also expanding its range of machining solutions.

Find out what SPK is all about, why CeramTec is reviving the SPK name for its machining activities and what other machining solutions CeramTec offers under SPK.

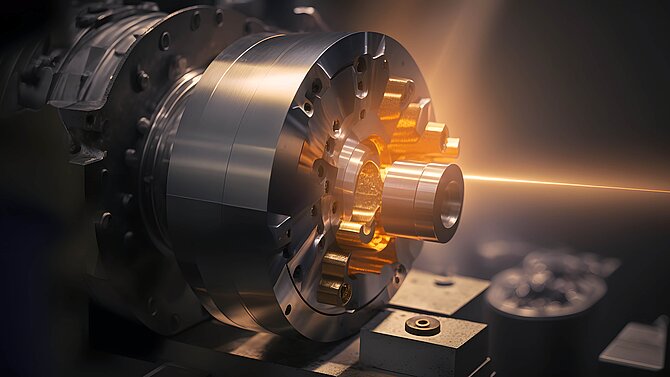

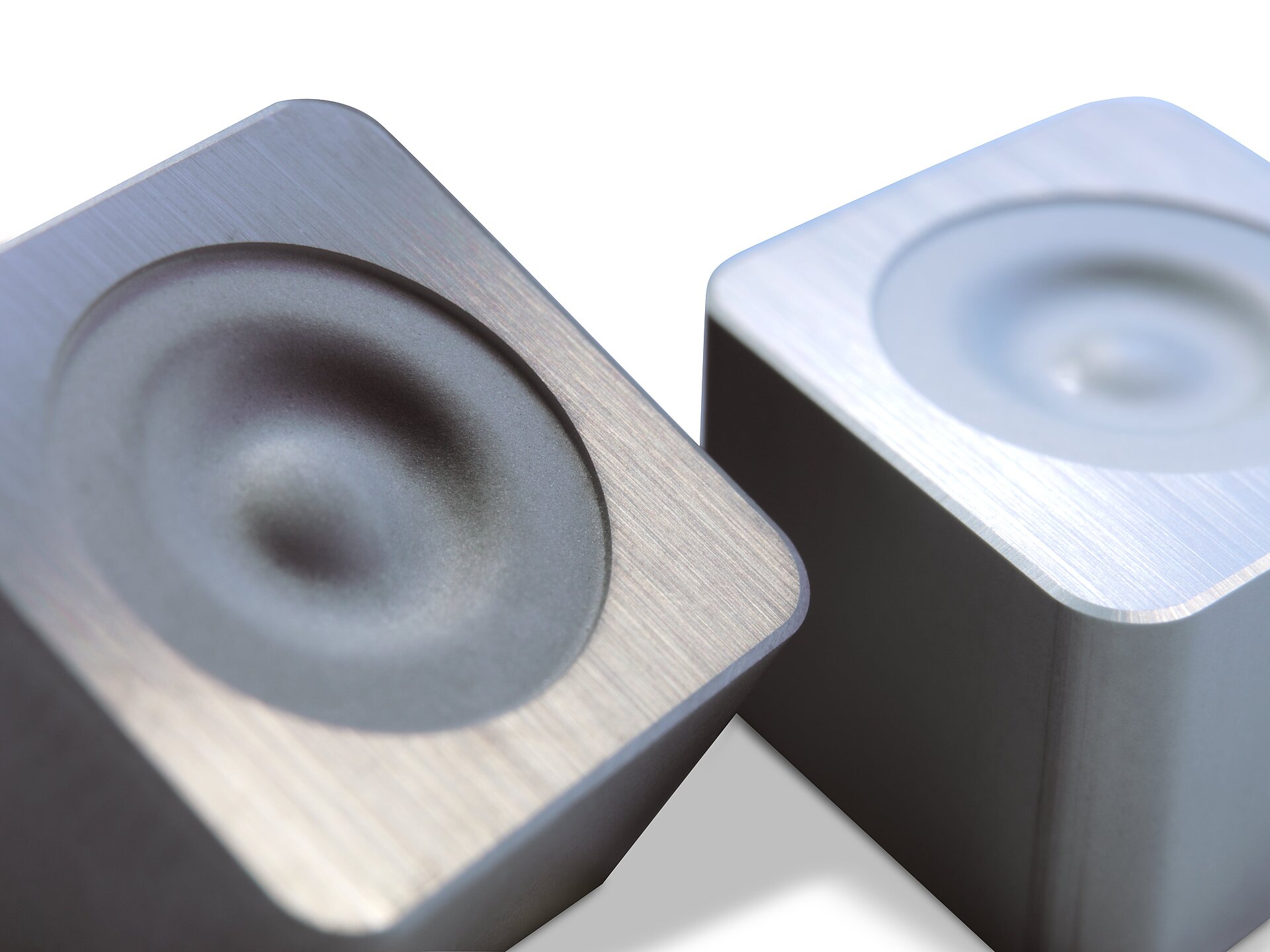

SPK® Cutting Inserts

Under the SPK® brand, CeramTec offers a unique range of indexable inserts made of ceramic cutting materials, CBN (polycrystalline cubic boron nitride) and whisker-reinforced ceramic for turning, hard turning, grooving, milling and boring in a wide range of industries.

The performance of a cutting material is the basis for the optimum machining of a workpiece. Its performance has a major influence on the most important machining parameters such as tool life, cutting speed and surface quality. With the SPK by CeramTec range of cutting materials and indexable inserts for workpieces made of cast iron, hardened and sintered steel and HRSA materials, a wide variety of machining tasks can be solved efficiently and economically.

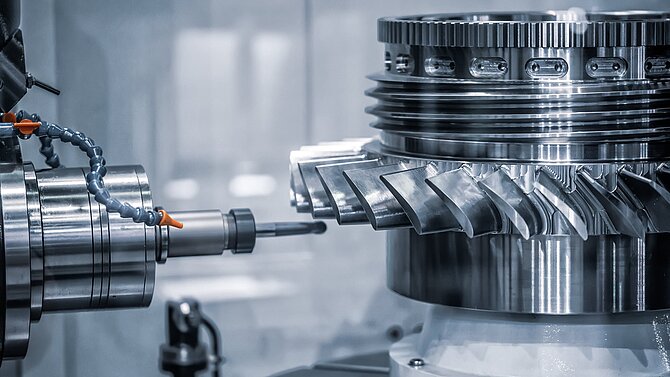

SPK® Engineering

The technological and economic requirements in machining technology are constantly increasing. The SPK® by CeramTec Engineering Team creates practice-oriented solutions with coordinated tool systems and comprehensive application know-how in the automotive, aerospace, transmission and bearing industries, mechanical engineering, the process industry, and power generation.

With its engineering services, our SPK® by CeramTec engineering team combines cutting materials and tools with components, materials, and the machine tool to create processes that enable high productivity and maximum possible safety.

Downloads & Brochures

Discover further information & brochures in our Machining Download Area.

SPK® by CeramTec - FAQ

What are the advantages of ceramic cutting materials?

Due to their properties, ceramic cutting materials usually enable significantly higher cutting parameters. This usually results in shorter machining times, especially for cast iron materials. They are characterised by high temperature resistance and good wear resistance. The result is increased productivity with reduced tool change costs.

For which materials are SPK® Cutting Tools particularly well suited?

SPK® cutting tools are ideal for machining cast iron, hardened steels and heat-resistant superalloys (HRSA). They really show their strengths in series production and high-performance processes. They also offer high process stability with these demanding materials.

Does SPK® provide support in selecting the right tools?

Yes, we support our customers from the selection of the cutting material and the design of the tool to implementation on site. Our experienced application team works with you to develop tailor-made solutions for your specific machining requirements. Our goal is always to achieve an optimally coordinated machining process with maximum efficiency.

What materials are used for SPK® cutting tools?

SPK® uses high-performance ceramics made from aluminium oxide, mixed ceramics, silicon nitride and α/β SiAlONe. High- and low-content CBN cutting materials and SiC whisker-reinforced ceramics are used as super-hard cutting materials. This enables optimum performance and precision to be achieved during machining.

How do ceramic-based cutting tools improve productivity?

In most cases, they enable higher metal removal rates and have improved tool life. They therefore optimise the main machine times and also the secondary machine times. This can lead to an increase in production efficiency.