Automotive & E-Mobility

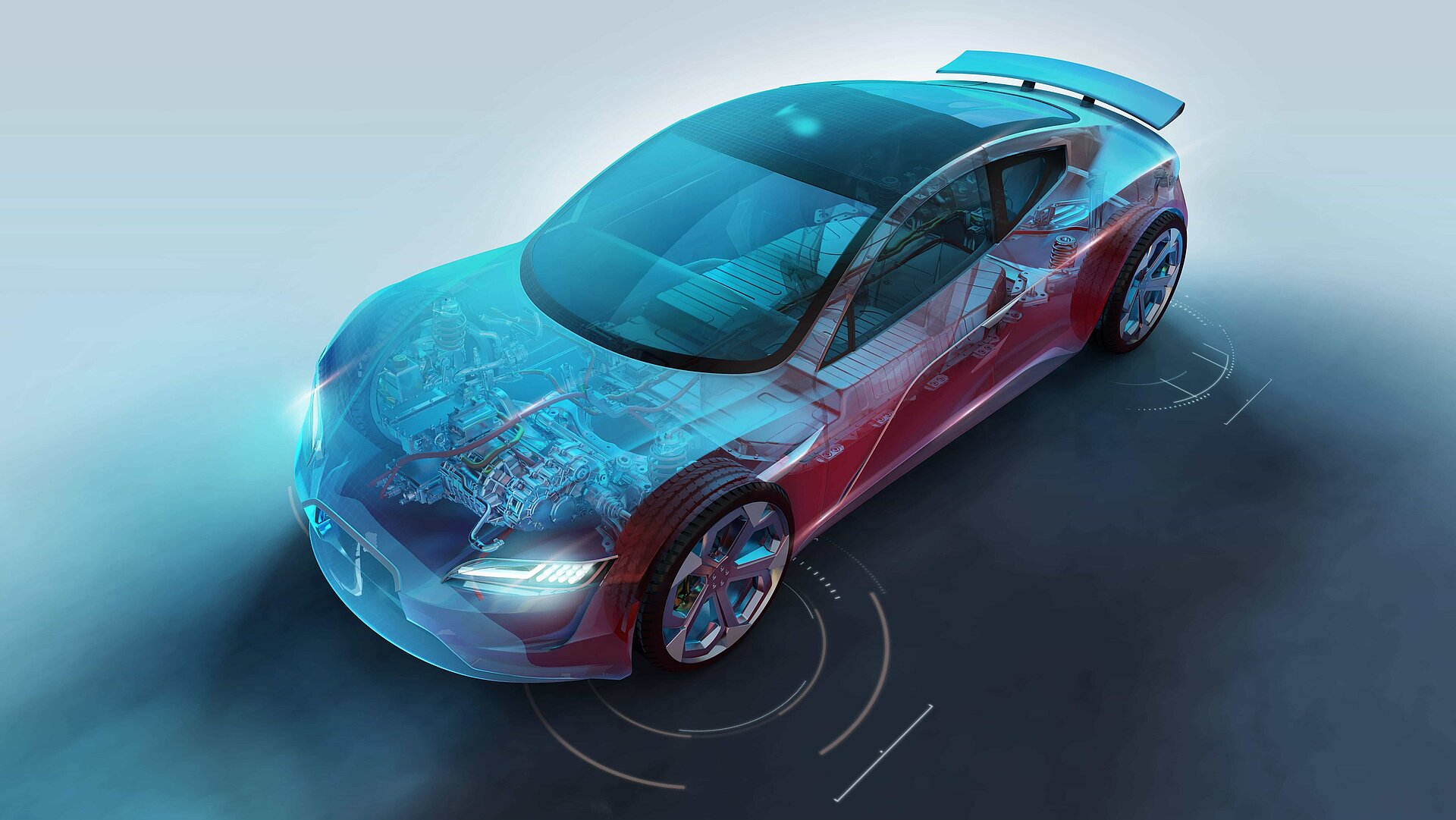

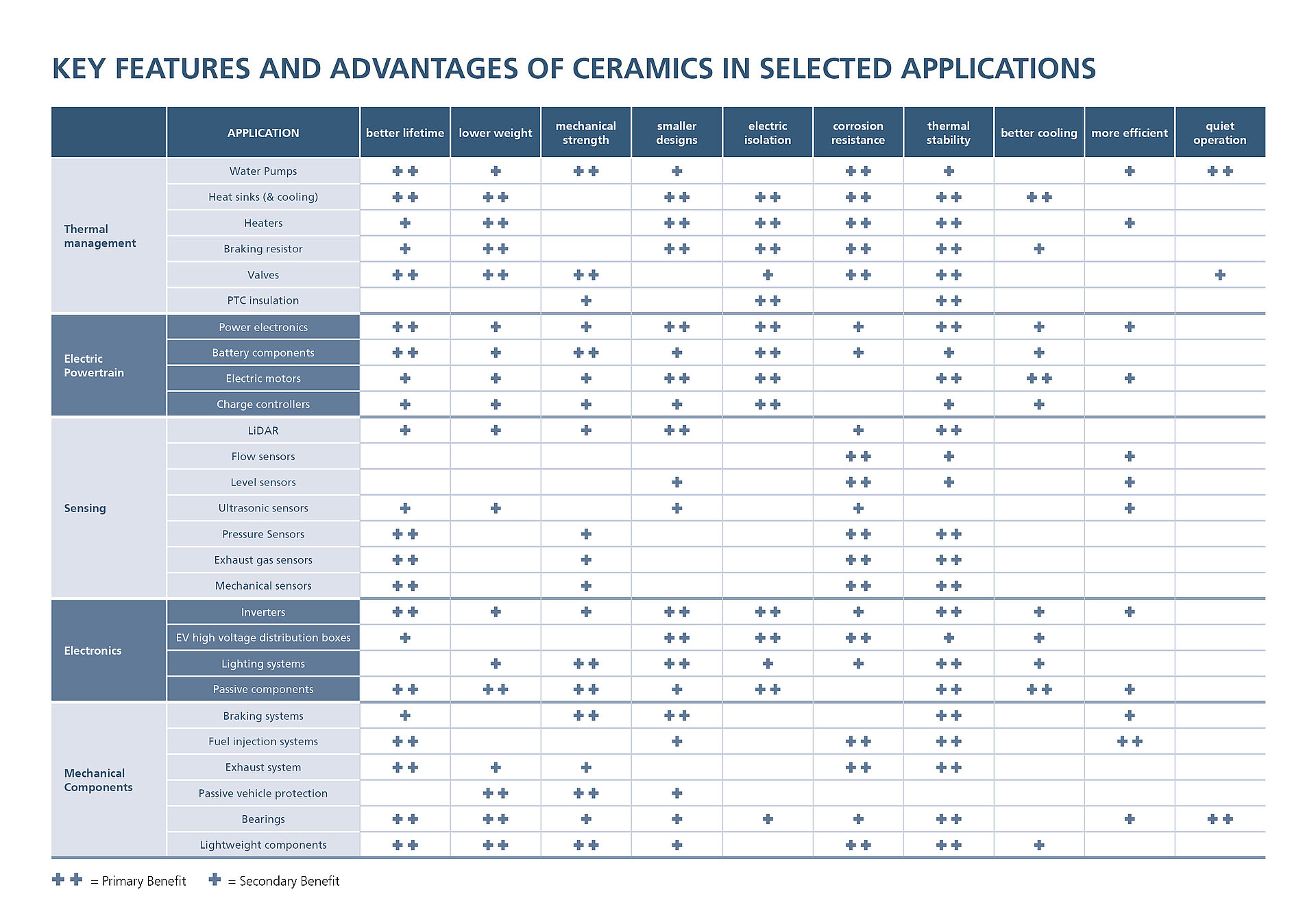

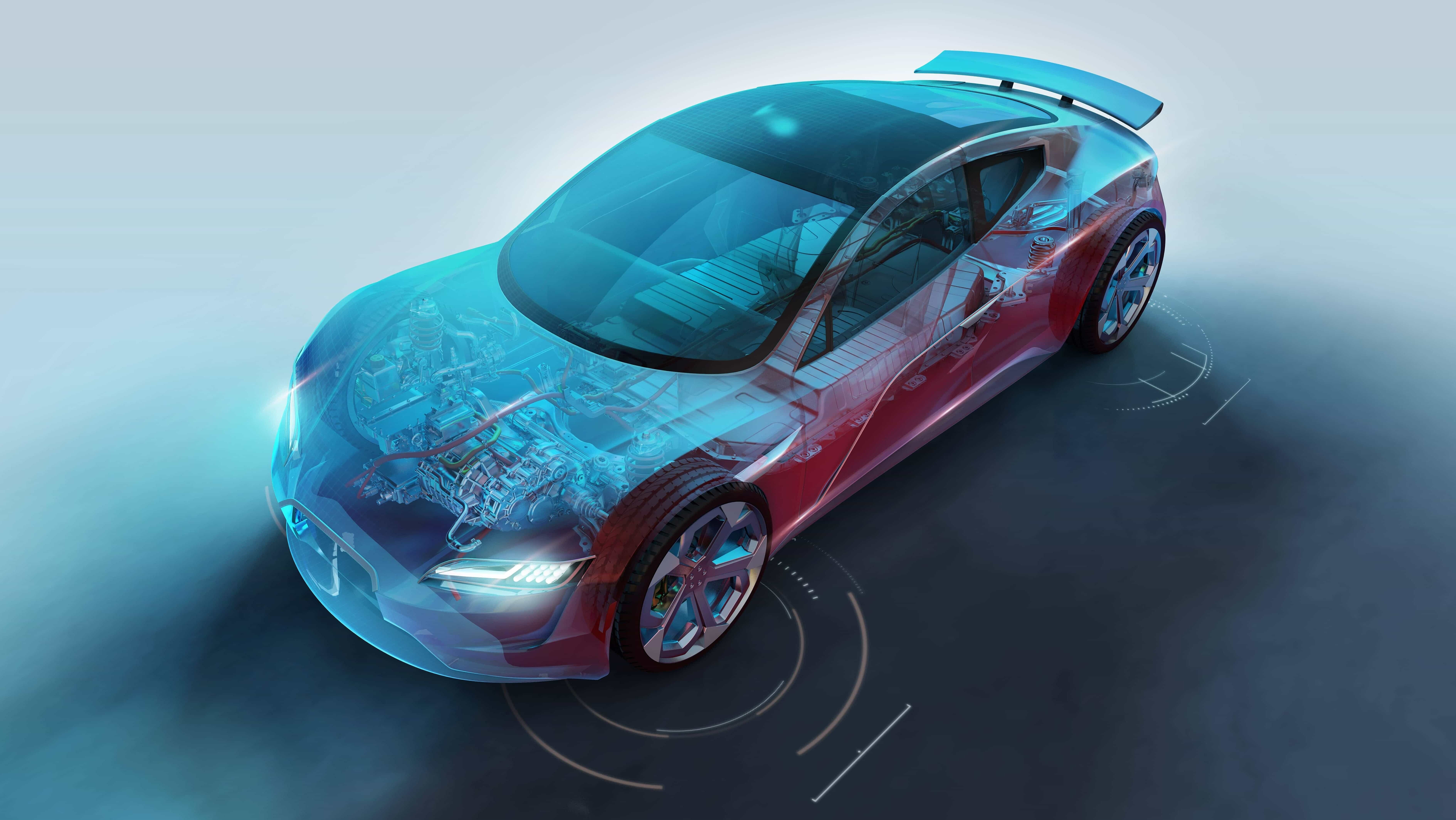

Technical ceramics are used in various areas of the automotive industry and e-mobility due to their outstanding material properties:In the vehicles themselves, in production facilities for vehicle construction and as components in a wide variety of applications, the use of advanced ceramics makes a significant contribution to increasing efficiency, comfort and safety.

In electric drive systems, high-performance ceramics serve as electrical insulation and protect components such as power electronics or sensors from high temperatures and electric flashovers. It is used in brake systems and bearings due to its high wear resistance and hardness, which leads to a longer service life and lower maintenance requirements. It is also used in batteries, where ceramics are used as separators to increase the safety and efficiency of lithium-ion batteries. Overall, the low weight of technical ceramics also helps to reduce the overall weight of vehicles, which is particularly beneficial for the range of electric vehicles.

As a recognised and experienced supplier of technical ceramics for the automotive industry, we are TISAX and IATF 16949 certified.

Areas of Use & Fields of Application

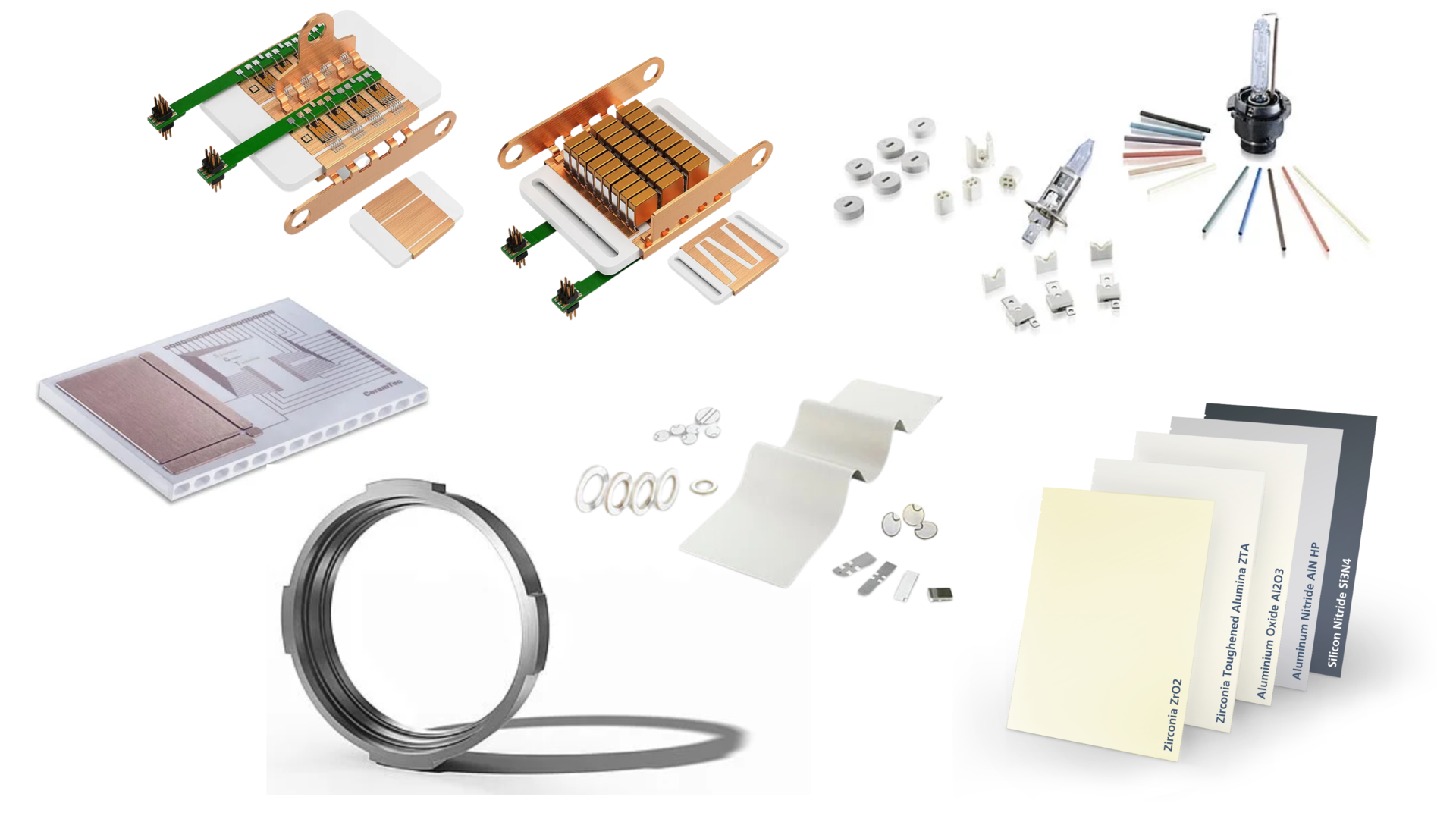

Thermal Management e-drive Train Sensors / Piezo Technology

Electronics Mechanical Components

Thermal Management

Heat Sinks | Substrates | Pumps, Valves & Components

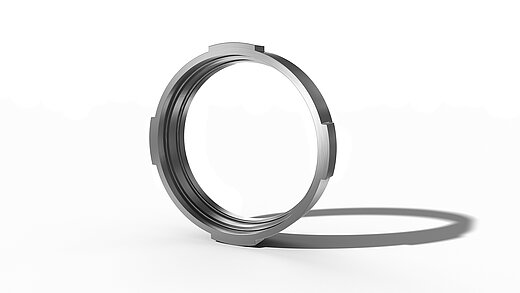

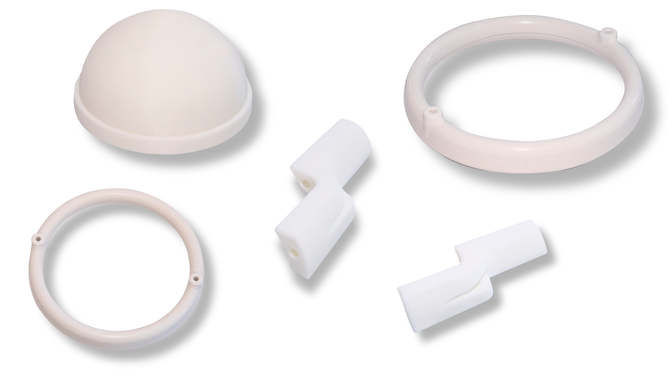

The use of high-performance ceramics in thermal management in the automotive industry offers decisive advantages due to their high thermal conductivity, temperature resistance and chemical stability. In water pumps and valves, wear-resistant components such as plain bearings and sealing discs ensure a long service life and energy efficiency with low friction.

Actively and passively used heat sinks and metallised substrates optimise heat dissipation in heaters and brake resistors, prevent overheating and increase reliability. PTC insulations benefit from the excellent electrical insulation and thermal stability of the ceramic and ensure safety and functionality even under extreme conditions.

e-drive Train

Heat Sinks | Substrates

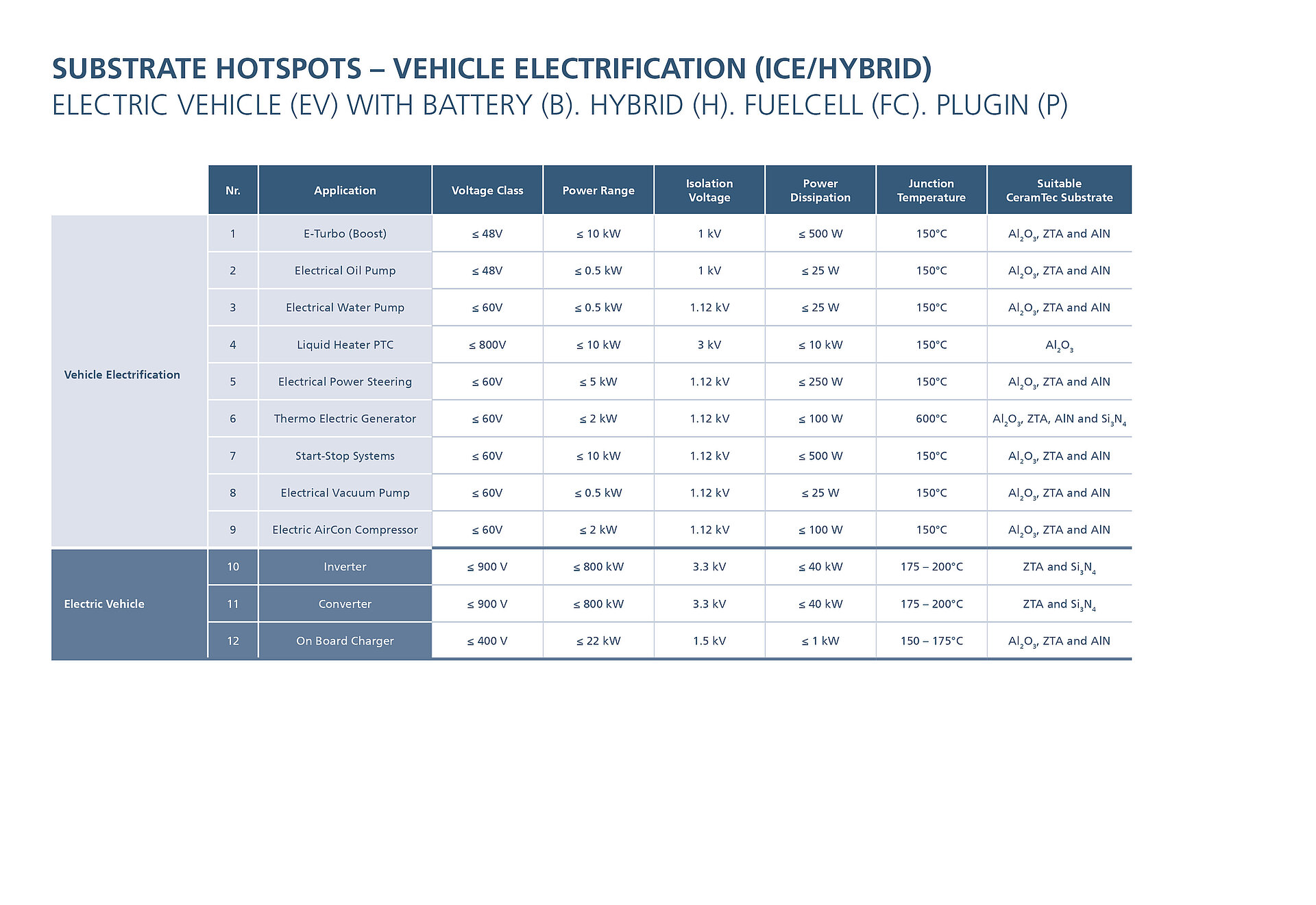

Technical ceramics offer decisive advantages in electrical powertrains thanks to their high thermal and electrical insulation as well as their wear resistance: In power electronics, metallised substrates and heat sinks ensure efficient heat dissipation and increase the reliability of power components.

Ceramic battery components and insulation components improve safety and service life thanks to excellent temperature resistance and chemical stability. In electric motors and charge controllers, wear-resistant roller bearings and insulating components optimise efficiency and operational reliability even under high loads.

Sensors / Piezo Technology

Piezoceramics | Sensors & Transducers

Ceramic sensors and piezo technology play a key role in the automotive industry as they enable precise and durable solutions due to their high temperature and corrosion resistance as well as their excellent electrical insulation. In applications such as LiDAR, ultrasonic and pressure sensors, piezo components and pressure cells provide precise real-time data that support safety-critical systems such as airbags and driver assistance systems.

Insulation components and ceramic housings protect against extreme environmental conditions and increase the reliability of flow, level and exhaust gas sensors. Power converters based on piezoceramics improve energy efficiency and enable the efficient conversion of mechanical energy into electrical energy, which is advantageous in actuators and in the generation of vibration energy.

Electronics

Heat Sinks | Substrates | Passive Components | Insulation

High-performance ceramics are also impressive in automotive electronics - particularly due to their outstanding thermal and electrical properties as well as their high temperature resistance. In inverters and EV high-voltage distributors, metallised substrates and insulation components ensure efficient heat dissipation, reliable electrical insulation and a compact design.

Passive components and lighting systems benefit from ceramic heat sinks and components for busbars, which ensure stable operation at high temperatures and improved energy efficiency. In addition, arc chambers made of technical ceramics increase the safety and service life of high-voltage applications thanks to their high corrosion resistance and arc resistance.

Mechanical Components

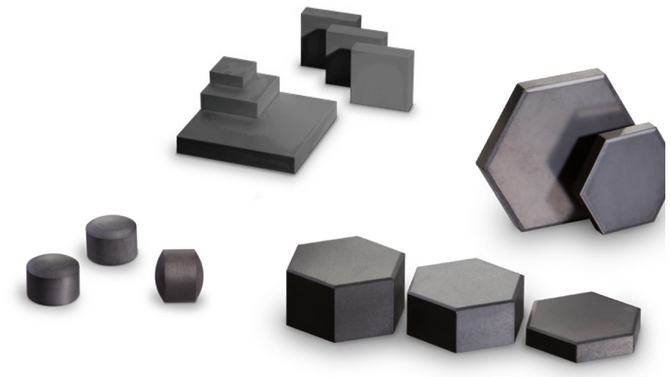

MMC Castings | Vehicle Protection | Brake Components & Rollers

In brake and injection systems, actuators, pistons and bushings enable precise control and a long service life even under high pressure and temperature loads. Exhaust systems benefit from ceramic exhaust flaps and feedthroughs that reliably withstand extreme temperatures and aggressive exhaust gases.

Rolling and bearing components and MMC castings made of ceramic contribute to weight reduction in lightweight construction without compromising on strength and load-bearing capacity. These properties also make technical ceramics ideal for passive vehicle protection, where they guarantee maximum safety and resistance to mechanical and thermal influences.

Download Area

Download Data Sheets | Download Brochures

Discover further interesting documents in our Download Center.