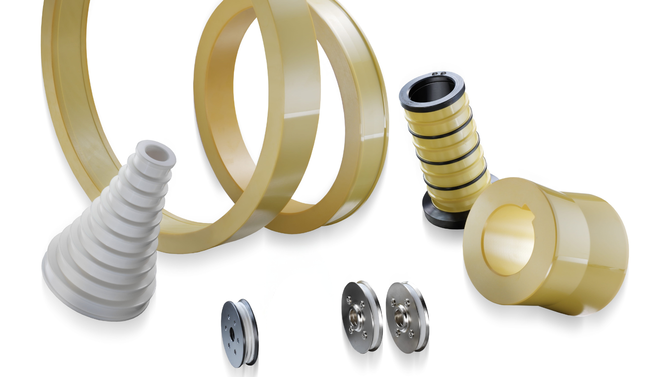

Wear-optimized Solutions and Tools for Wire Drawing, Tube Forming and Forming Systems

Forming tools are subject to extreme stress and high levels of wear. Technical ceramics are far superior to other materials in these conditions. CeramTec ceramic tools deliver enhanced performance and increased economy in every step of the metal forming process.

When forming metals – either in casting, rolling, tube drawing, bending or widening – the tools that are used are subject to tremendous forces and stress. Depending on the material used, these tools can suffer extreme wear. This is why the forming process is yet another field where advanced ceramics from CeramTec offer convincing proof of their strengths.

Zirconium Oxide, Alumina and Silicon Nitride are the advanced Ceramics used in the Forming Process

From the over 150 ceramic materials CeramTec has developed for specific applications, three types of advanced ceramics have proven themselves in the forming process in particular:

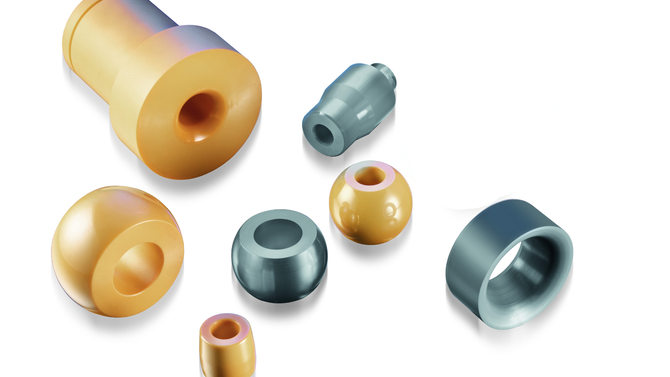

Zirconium Oxide ZN40 in the Forming Process

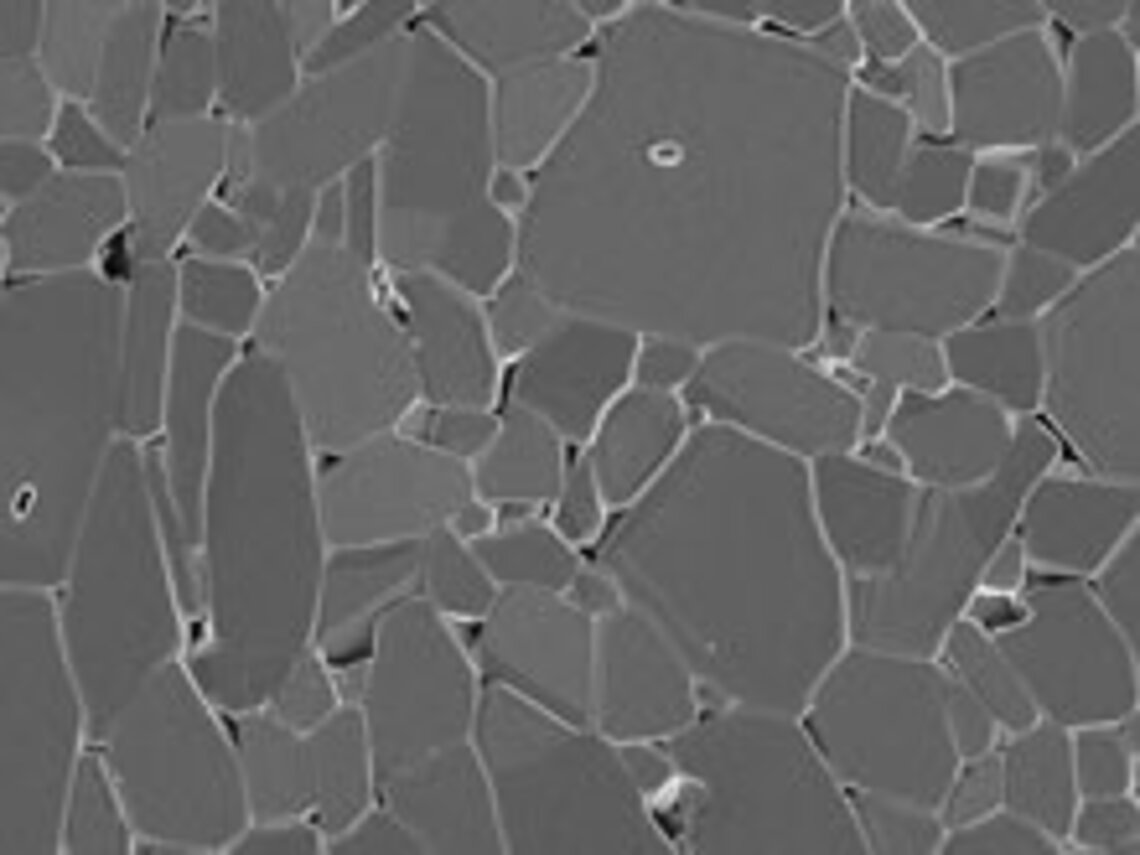

Zirconium oxide (ZrO2) produces extremely strong and rigid components. Alongside its excellent tribological properties with respect to friction and wear on objects that move in opposite directions, its wear resistance, corrosion resistance and electrical and thermal insulation properties make CeramTec ZN40 zirconium oxide ceramic the ideal material for equipment and mechanical engineering. Zirconium oxide is gaining ground as a structural material for components subject to high stress.

Aluminum Oxide B601 in the Forming Process

Alumina (Al2O3) is one of the most well-known oxide ceramic materials. CeramTec has developed a wide range of low-density and lightweight materials with a variety of property combinations. The CeramTec alumina ceramic B601 has proven itself in the forming process.

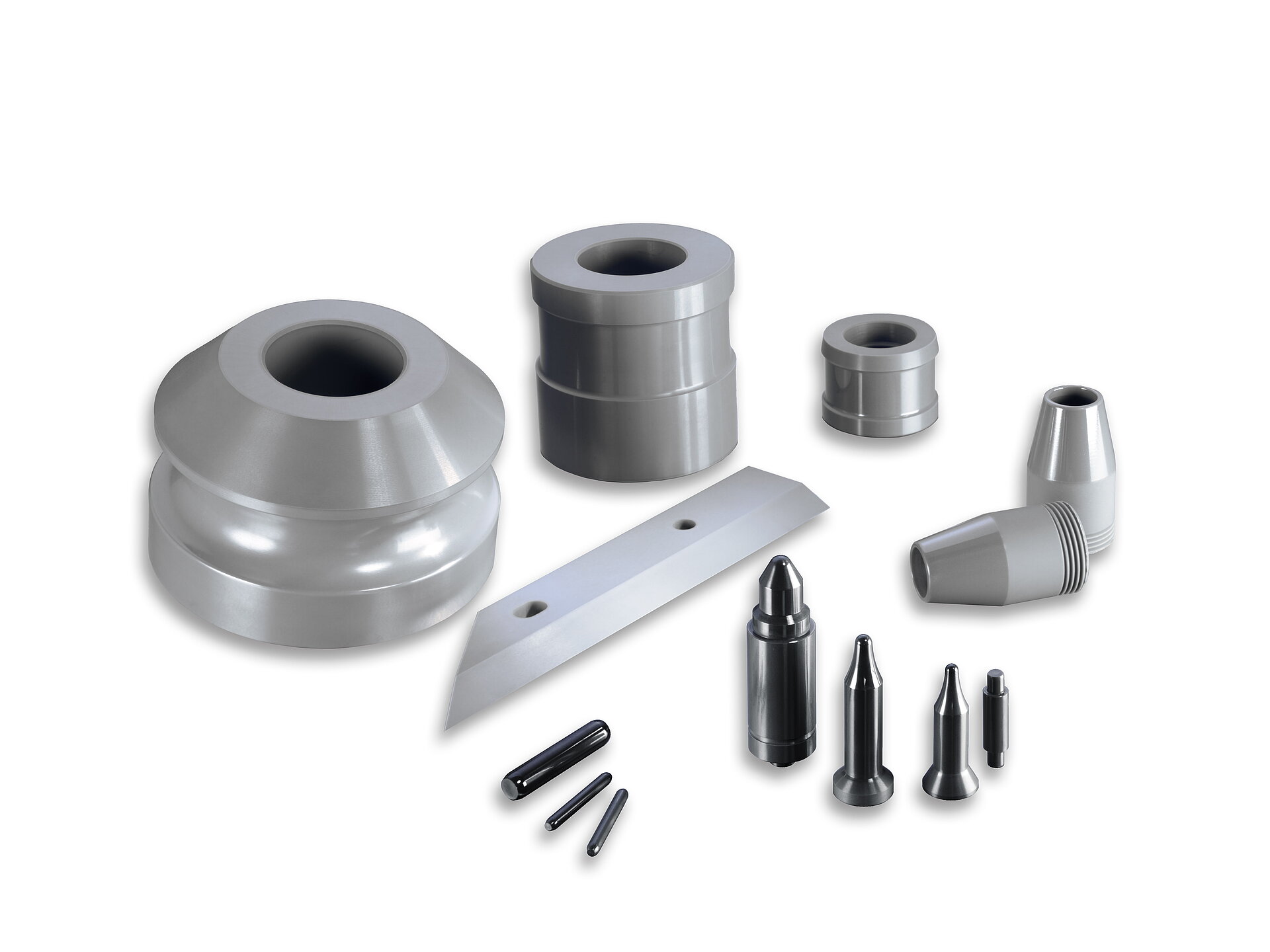

Silicon Nitride SL200BG in the Forming Process

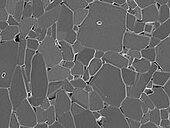

Silicon nitride materials (Si3N4) are perfectly suited for manufacturing mechanically stressed components, even and especially at high temperatures. CeramTec SL200BG silicon nitride ceramics possess excellent characteristics for use in forming and are also employed in welding process applications.