Peak Performance for the Industry

CeramTec Industrial is your experienced and reliable partner in the world of high-performance ceramics.Whether at home, in the office, in industrial production or in transport - technical ceramics are present almost everywhere and deliver top performance, often without us even realising it.The various ceramic materials are used where conventional materials reach their limits:At extreme temperatures, high loads, electrical requirements - and even in the human body.

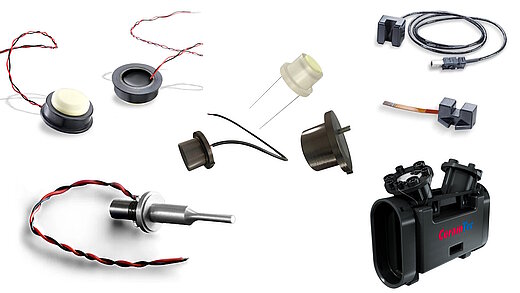

The possible applications are diverse: from the automotive industry and electronics to high-tech applications in semiconductor production. CeramTec supplies reliable solutions that increase the efficiency and sustainability of production processes. Technical ceramics not only enable safe and comfortable mobility, but also contribute to the provision of clean energy. They make decisive contributions to digital communication in increasingly compact devices and in many cases improve the quality of life in our everyday lives.

Discover the world of high-performance ceramics with CeramTec. Let's work together to develop innovative solutions that meet the requirements of the future and transform the industry in the long term.

Expertise for the Industry

The applications of technical ceramics are as diverse as the advantages of ceramic high-performance materials.

In industry alone, our solutions can be found in around 200 products & applications. Let us inspire you and discover our diversity - practically sorted by products & applications, markets and materials.

Technical Ceramics

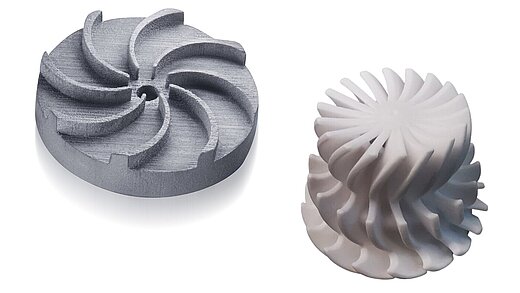

High-performance ceramics are fascinating due to their exceptional properties, which enable them to withstand extreme conditions such as high temperatures and mechanical stress. By combining outstanding mechanical stability with high heat and corrosion resistance, it plays a decisive role in many high-tech applications and contributes to the development of sustainable and efficient technologies.

Fascination of Advanced Ceramics

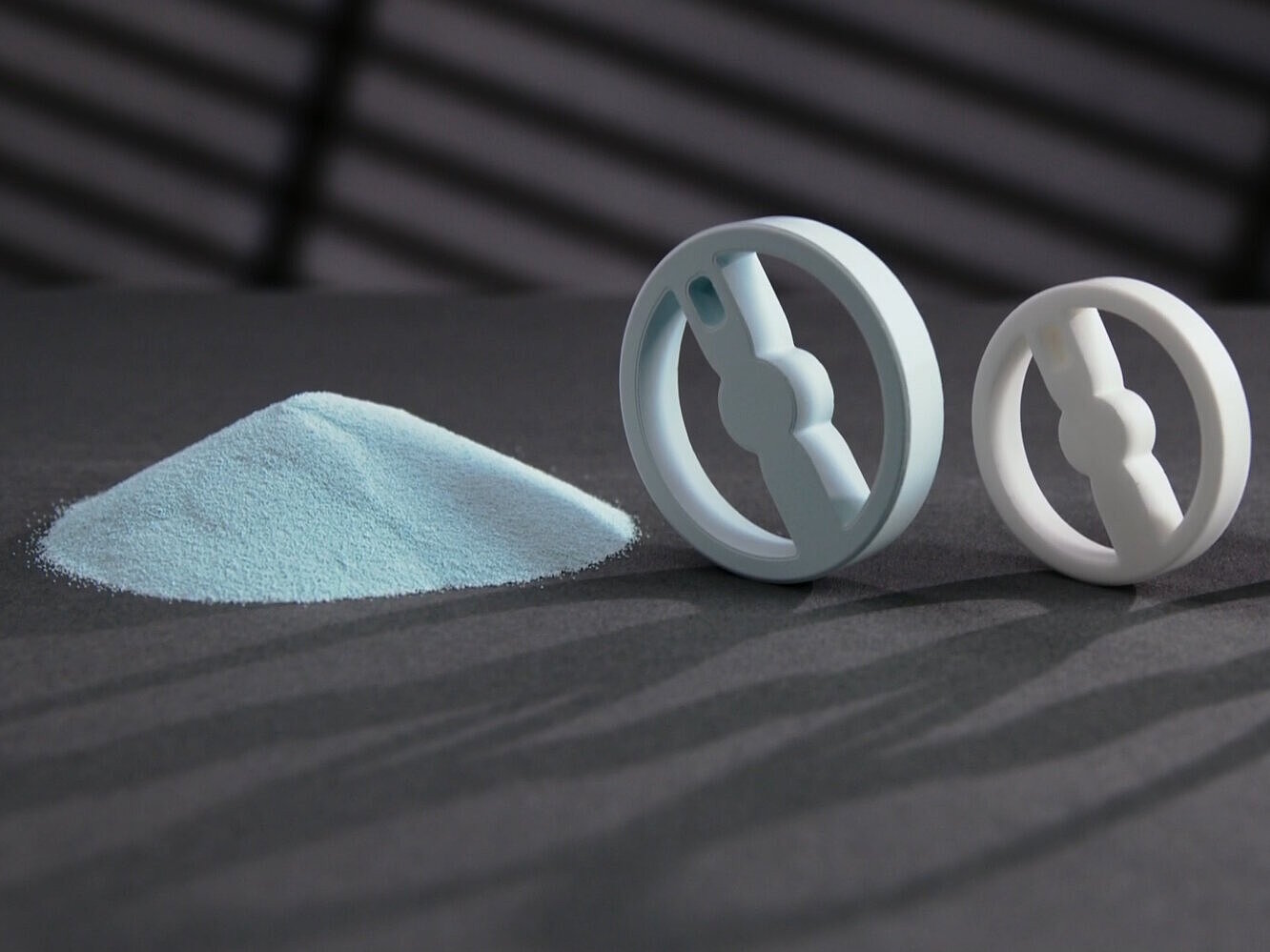

Let us inspire you with the fascinating possibilities of high-performance ceramics!

Immerse yourself with us in the production of this material of the future - from its origins in the form of silicates and metallic compounds in the earth to specialised high-end solutions for the challenges of the future.