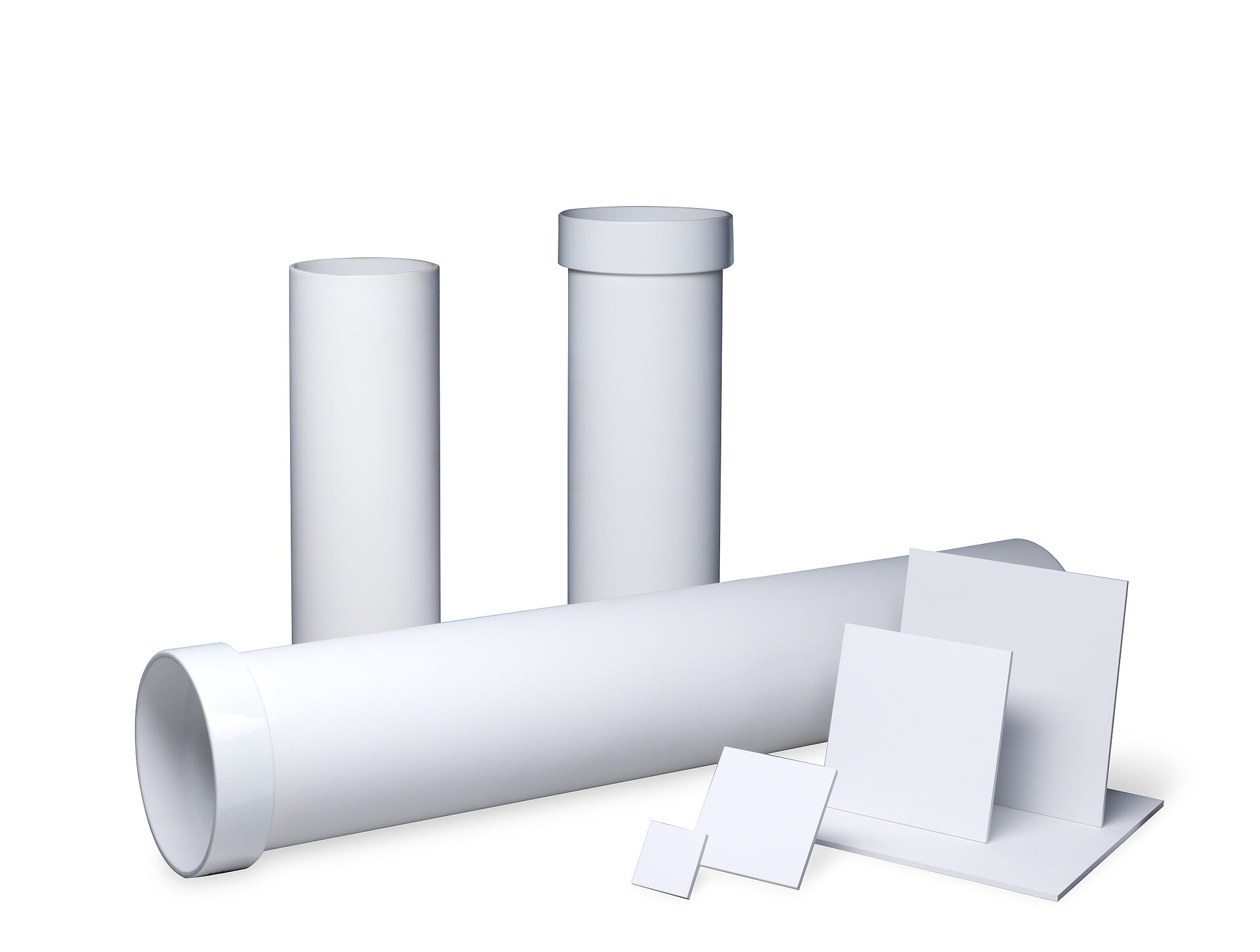

Ceramic Pipes and Tubes

Imagine if you could optimise industrial processes with materials that are not only extremely temperature and corrosion resistant, but also offer the highest precision and durability - even under the toughest conditions. At CeramTec, we develop customised tubes and pipes made of high-performance ceramics that are indispensable in areas such as filtration, electroplating, temperature measurement and foundry technology. Let us work together to find innovative solutions for your specific requirements.

Our Ceramic Pipes & Tubes

- Pipes and Tubes made from Alunit® Aluminum Nitride Ceramics

- Pipes made from ROCAR® Silicon Carbide Ceramics

- Tubes made from Rubalit® Alumina Ceramics

- Silicate Ceramic Thermocouple or Circuit Breaker Tubes

- ALOTEC® Wear Protection for Pipes and Linings

- Pipes made from Aluminum Titanate for Foundry Technology

- Thermocouple and Protection Tubes

- High Alumina Porous Pipes

- Ceramic multi-channel Tubes for Filtration

Pipes and Tubes made from Alunit® Aluminum Nitride Ceramics

We have succeeded in achieving series extrusion of exceptionally thermally conductive Alunit® aluminum nitride ceramics. This process enables rod-shaped bodies and tube systems made of ceramic with a thermal conductivity of ≥ 200 W/mK, high mechanical stability and dielectric strength.

ALOTEC® Wear Protection for Pipes and Linings

ALOTEC® is a highly specialized ceramic material for industrial corrosion and wear protection and is used widely to protect pipes and pipe systems from wear. Highly turbulent areas in particular, arcs, pipe necks, manifolds and inlet pipe ends often experience extreme wear. Ceramic linings with ALOTEC® achieve much longer a service life compared to steel.

Pipes made from Aluminum Titanate for Foundry Technology

Dosing and riser tubes manufactured from aluminum titanate ceramics (ATI) easily master the challenging working conditions in non-ferrous molten metal applications and have proven their efficacy in foundry technology. Aluminum titanate’s versatility makes it possible to produce a number of different pipe shapes with a variety of diameters and lengths up to 1,750 mm.

Thermocouple & Protection Tubes

Ceramic thermocouple tubes are used to manufacture temperature measurement and control devices and are designed with alumina or silicate ceramics. They are available as multi-bore tubes for use as RTD resistor temperature sensors and resister thermometers (RTD = Resistance Temperature Device).

High Alumina Porous Pipes

For most of the ceramic manufacturers, a pore is a flaw that has to be avoided. Very few of them can incorporate pores with predefined properties in ceramic materials. CeramTec designs and manufactures ceramic products with variable porosity and pore sizes for versatile applications.