Zirconia Toughened Alumina Substrates

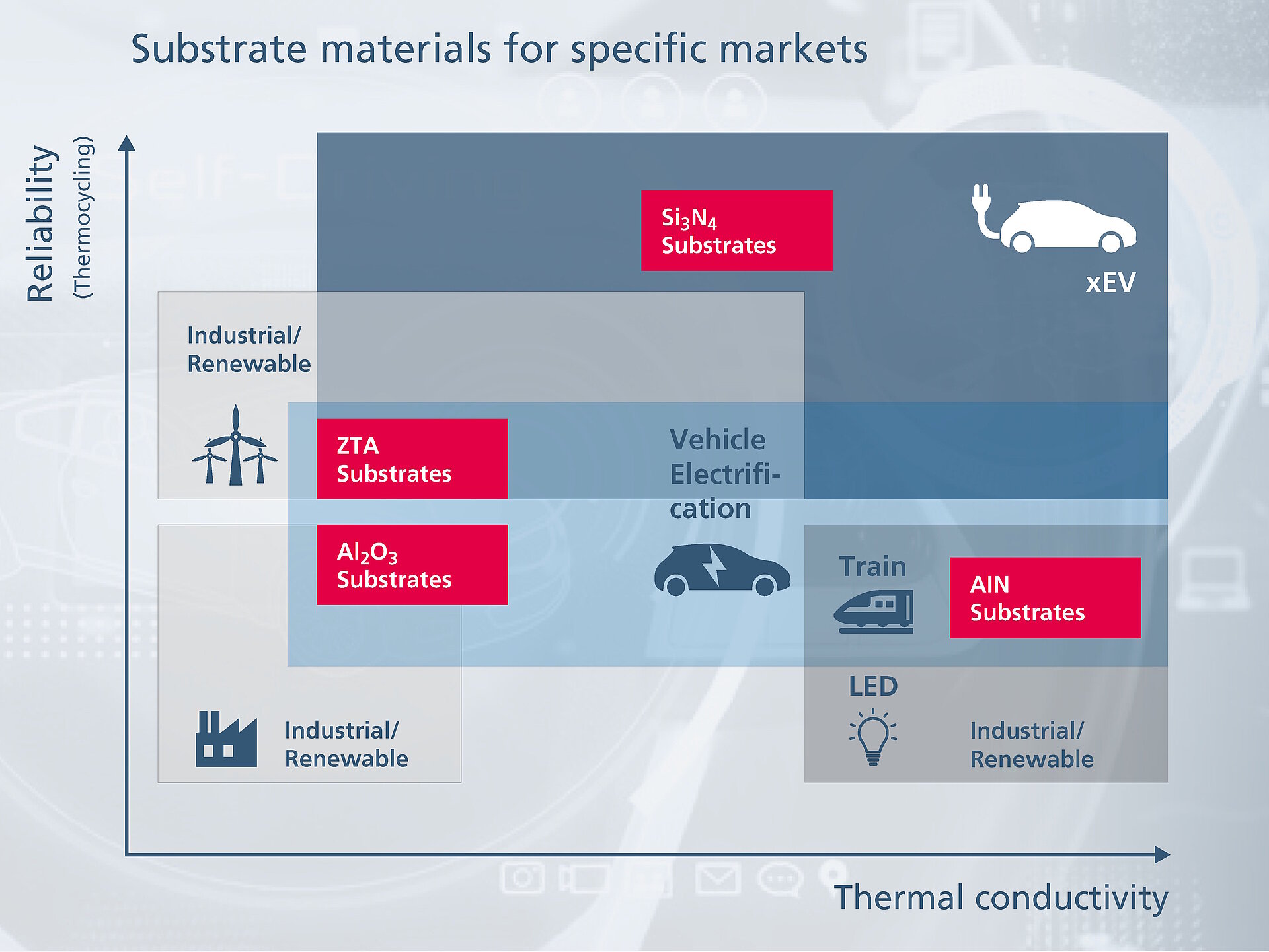

Substrates made of zirconia toughened alumina (Rubalit® ZTA) impress with their high bending strength (700 MPa), increased reliability (thermocycling) and a dielectric strength of AC/DC: ≥ 25 kV/mm. ZTA is used in industrial applications, xEV (electric vehicles) as well as in the renewable energy sector.

In May 2023, the substrate Rubalit® ZTA was added to CeramTec's comprehensive product portfolio. ZTA is a mixed ceramic - consisting of aluminium oxide ceramic, which in turn is toughened with zirconium oxide particles. This combination has improved the properties of pure aluminium oxide. Increased fracture toughness, flexural strength and dielectric strength make the Rubalit® ZTA substrate more resistant to mechanical stress.

The thermal conductivity is more than 27 W/mK and the dielectric strength reaches 25 kV/mm. This makes Rubalit® ZTA significantly superior to common PCB materials, for example. Its thermal conductivity, temperature resistance and insulation properties also make the substrate an ideal material for use in passive components or chip resistors.

Interested? David Hassler, Product Manager E-Mobility at CeramTec, explains in a short interview why manufacturers of power electronics need the new ceramic substrate Rubalit® ZTA.

Technical Values & Parameters

Physical properties

- Density: ≥ 4.0 g/cm3

Surface properties

- Ra value: ≤ 0.4 µm

Mechanical properties

- Bending strength DR sigma 0 (3 Point Method): ≥ 700 MPa

- Fracture toughness (IF method): ≥ 3.5 MPa*√m

- Young´s modulus: ≥ 310 GPa

- Vickers hardness: not specified

Thermal properties

- CTE: 100-800°C: +/- 6.9 -10.3 10-6/K

- Specific heat capacity at 25°C: ≥ 0.72 J/gK

- Thermal conductivity at 20°C: 27.0 W/mK (+/- 10% measurement tolerances)

Electrical properties

- Dielectric constant at 1 MHz: +/- 10.2

- Dielectric loss factor at 1 MHz: ≤ 2 (10-3)

- Volume resistivity at 20 °C: ≥1014 Ω cm

- Dielectric strength: ≥ 25 kV/mm

Geometry

- Standard size: 7.5“ x 5.5“ (+/- 1.2%)

- Thickness: 0.25/0.32/0.5/0.63 (+/- 10%)

- Warpage/camber: 0.2 - 0.6 %

Substrate as fired

- Length and width tolerance: +/- 1.5

- Thickness tolerance: +/- 12.5%