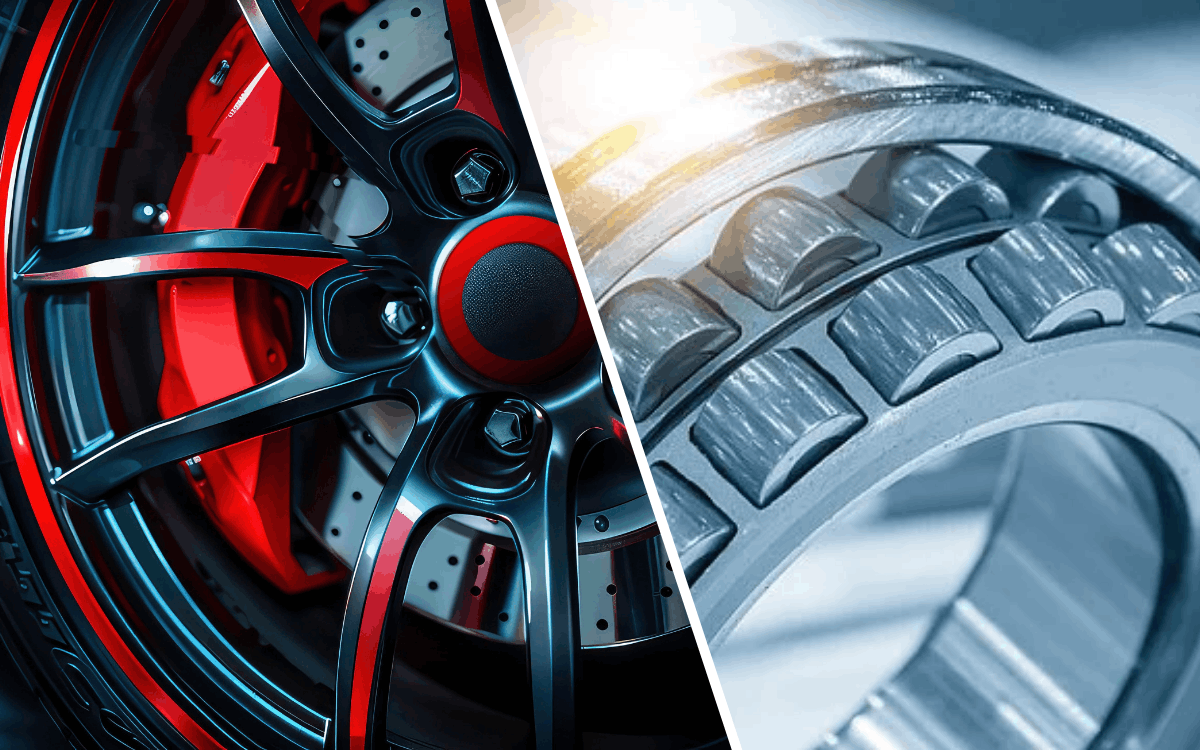

In modern vehicles, ceramic components are increasingly taking on key roles in dynamic systems. Wherever components move, transmit forces, experience temperature fluctuations, and/or are exposed to electrical influences, conventional materials reach their limits.

CeramTec develops advanced ceramic solutions precisely for these demands – from thermally stressed insulating rings for brake applications to high-precision rolling and bearing components. Our ceramics ensure stability, consistent performance, reduced thermal load, and increased service life in dynamic and safety-critical vehicle components.

Technical ceramics are characterized by low thermal conductivity and high temperature resistance. In dynamic systems, this reduces unwanted heat transfer to adjacent components and ensures stable, safe operating conditions – both in thermally stressed braking applications and in rotating systems exposed to fluctuating temperatures. As a result, functional reliability is maintained even under repeated load cycles and high operating temperatures.

Ceramic materials have a significantly lower density than many metallic alternatives. In moving and rotating components, this results in reduced mass and inertia forces. This improves the responsiveness of dynamic systems, increases energy efficiency, and has a positive effect on both service life and performance – particularly in highly dynamic vehicle applications.

Ceramics retain their precise geometry even under high temperatures and pressures, whereas metals can expand and potentially deform plastically when exposed to heat. As a result, ceramics enable precise fits, uniform force transmission, and low-wear operation of components over long service lifetimes.

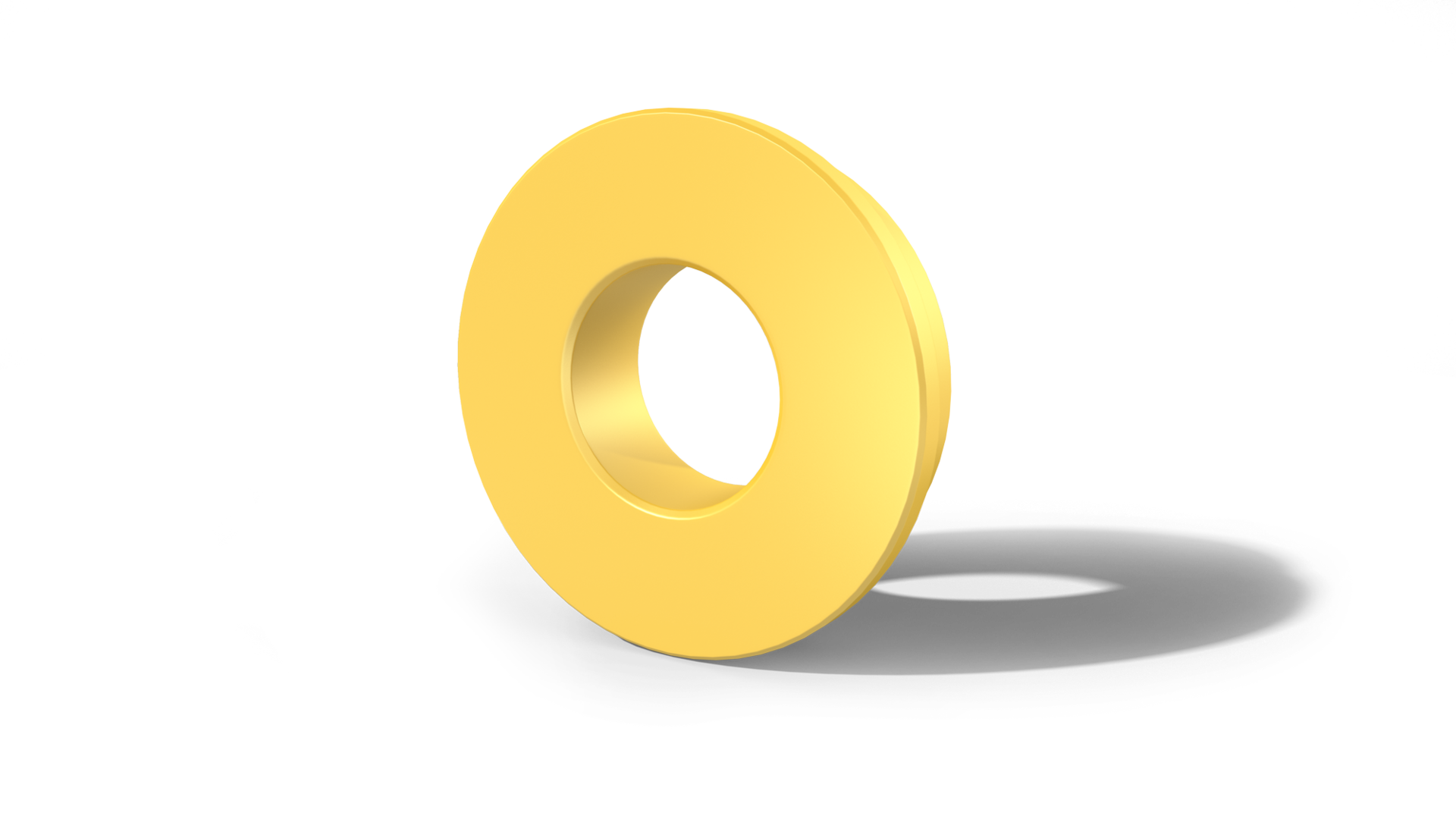

The brake piston is the central moving element within the brake caliper. It transfers the hydraulic pressure of the brake fluid directly to the brake pad – and thus to the brake disc. In doing so, it is exposed to extreme thermal and mechanical stresses:

- Extreme heat due to friction between the brake disc and the pad surface

- Pressure peaks due to braking processes

- Chemical stress from brake fluid, water and road salt

A brake piston must withstand these stresses permanently — without deforming or conducting heat further. Ceramic insulating rings are located directly in the moving area of the braking system. With each braking operation, they transmit pressure, limit heat transfer, and ensure the geometric stability of the assembly — even under extreme load cycles.

This is precisely where the advantages of ceramic insulating rings between the brake piston and brake pad come into play, especially when made from high-performance materials such as zirconium oxide (ZrO₂). Compared to metallic solutions, they effectively reduce heat conduction to the brake fluid, prevent functional losses during repeated high-load braking, and contribute to consistent braking performance throughout the component’s lifetime.

Zirconium Oxide (ZrO₂)

Zirconium oxide (ZrO₂) is the preferred ceramic material for insulating rings in brake systems, as it is specifically engineered for applications where high thermal loads, mechanical pressure, and dynamic load cycles occur simultaneously.

It is ideal for performance and premium road vehicles, commercial vehicles in continuous operation, electric vehicles with a focus on efficiency, and applications with high thermal stress.

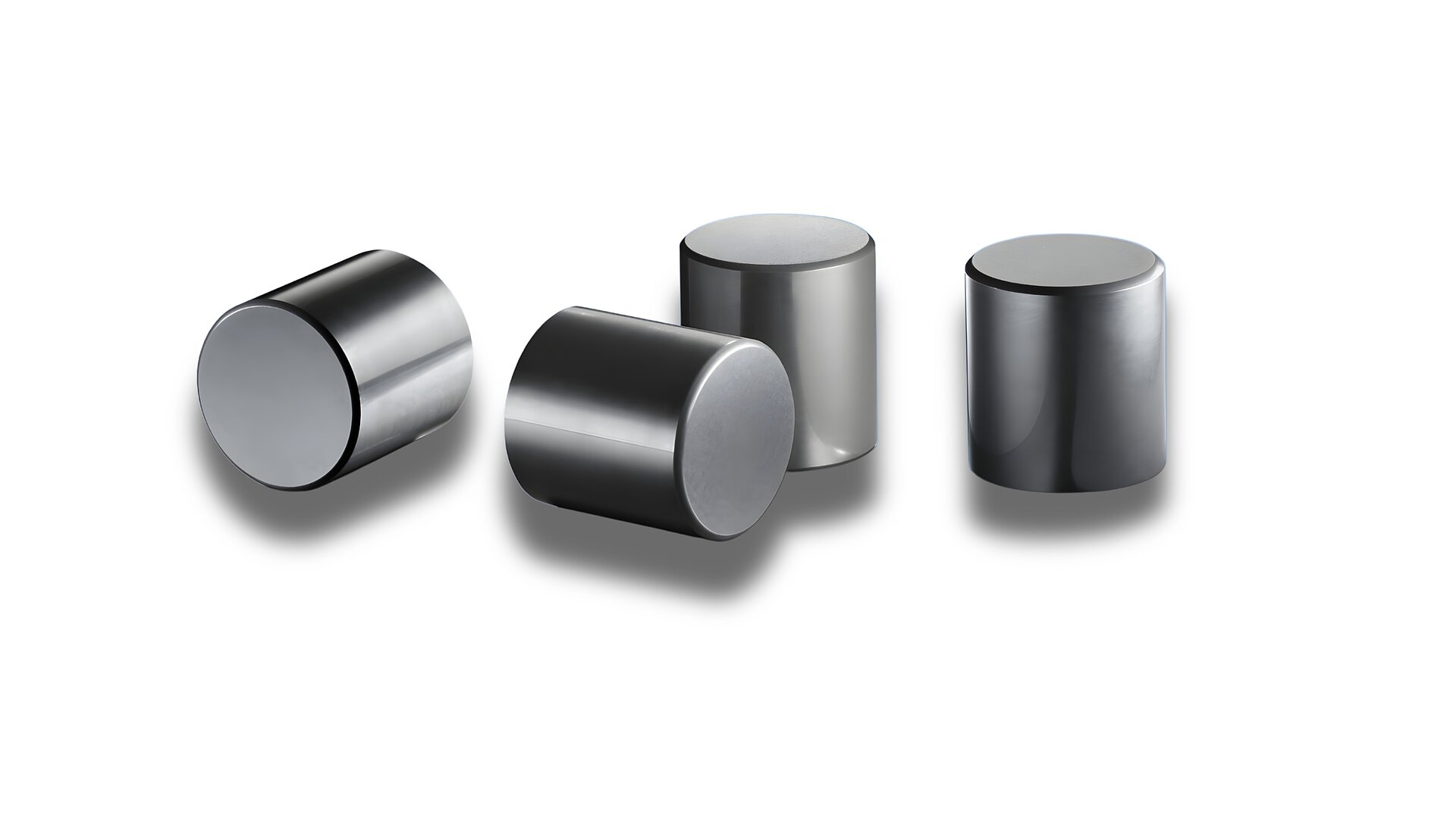

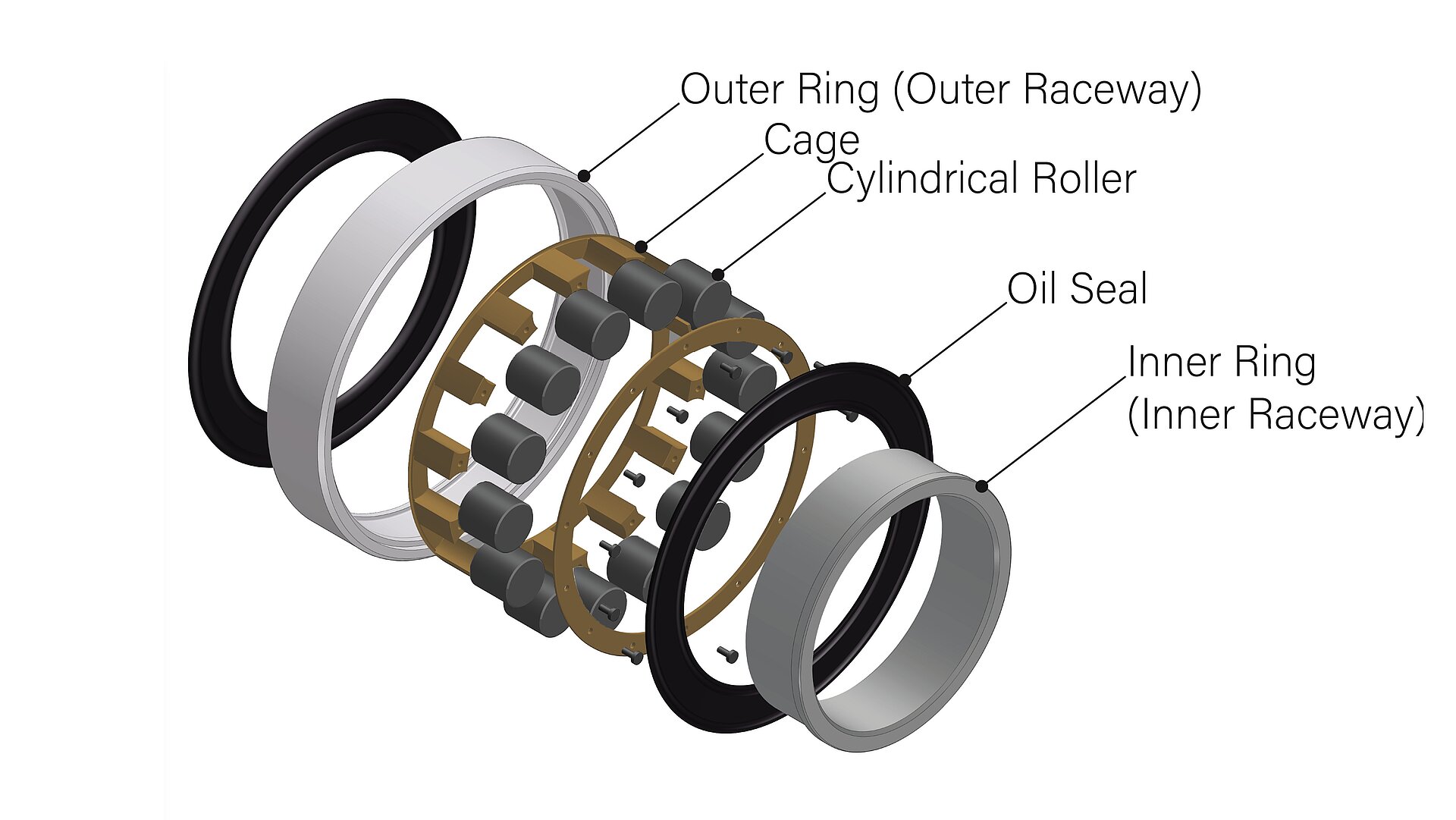

Our ceramic rollers made of silicon nitride (Si3N4 SL900) are specially developed for demanding mobility applications and are used wherever components must reliably withstand high speeds, changing temperatures, electrical influences or aggressive media. They are an integral part of bearing and guidance systems and have a direct influence on efficiency, service life, and operational reliability.

Ceramic rollers combine low weight, high wear resistance and long service life.

Thanks to their emergency running properties, they protect adjacent components even in the event of lubricant interruptions, while their dimensional stability ensures precise fits at changing temperatures. Electrically insulating and non-magnetisable, they can be used safely in sensitive electronic environments.

Hybrid Bearings vs. Conventional Steel Bearings

Ceramic hybrid bearings with silicon nitride SL900 rollers are increasingly replacing traditional steel bearings, especially in environments with high demands on service life, precision and corrosion resistance. They offer electrical insulation, which prevents current flow through the bearing. At the same time, their high corrosion resistance in humid or aggressive media is impressive. Thanks to their low mass and dimensional stability, the bearings can be easily integrated into existing designs without the need to adjust the installation space or design. Applications benefit in the long term from lower wear, longer service life and stable performance, especially under demanding operating conditions.

Silicon Nitride (Si₃N₄)

Silicon nitride (Si₃N₄) is the preferred material for ceramic rollers in rotating systems with high speeds and varying loads. Its low density reduces rotational mass, improving the running behavior and efficiency of bearing and guiding systems.

It is ideal for hybrid and high-performance bearings, as well as those used in electric motors and electrified drivetrains.

- Low density – reduces rotational mass and increases efficiency

- Non-magnetic and electrically insulating – safe operation in electronic systems

- Shape stability – low thermal expansion and high modulus of elasticity ensure precise fits under changing temperatures

- Mechanical robustness – high compressive and flexural strength with minimal wear