CeramTec - Your Machining Expert

Are you faced with the challenge of machining heat-resistant superalloys or hardened materials economically and reliably? Or would you like to optimise the service life of your tools and increase the productivity of your production?

SPK® Cutting Tools supports you with over 70 years of experience in machining technology and offers you customised solutions - from innovative cutting materials such as SiAlON and CBN to individually designed special tools. Our SPK® engineering team will work with you to analyse the entire machining process and develop strategies to make your production more efficient and reliable.

Discover how we can take your machining processes to the next level.

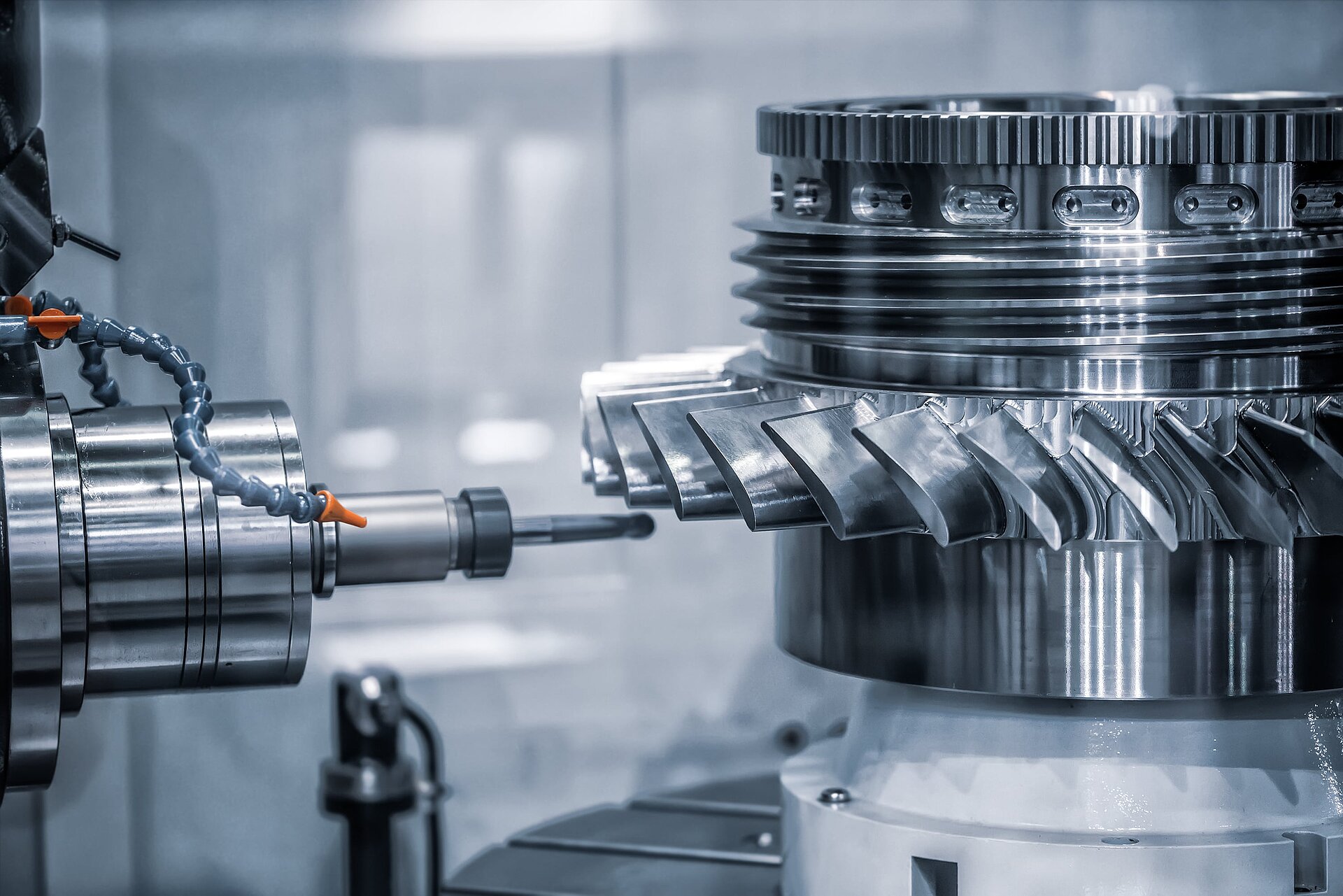

Machining of Heat Resistant Super Alloys

Cutting materials play a decisive role in the machining of components made of nickel-based alloys. That is why, in addition to our whisker ceramics, we also offer you our SiAlON cutting materials for turning, grooving and milling. Because SiAlON cutting materials are an excellent economical and process-safe alternative for machining heat-resistant nickel-based superalloys with high cutting values in a process-safe manner.

Would you like to test the performance of our SiAlON cutting materials?

Cast Iron Machining

Machining cast iron - we offer you over 25 ceramic cutting materials and a various number of different CBN cutting materials. There is bound to be a cutting material that is best suited to solve your machining problem. When we combine the machining task with our cutting materials and tool holders and our more than 60 years of machining experience, the result is machining solutions in your production that are characterized by high economic efficiency and process reliability.

Curious about what 25 ceramic cutting materials can do for you in cast machining?

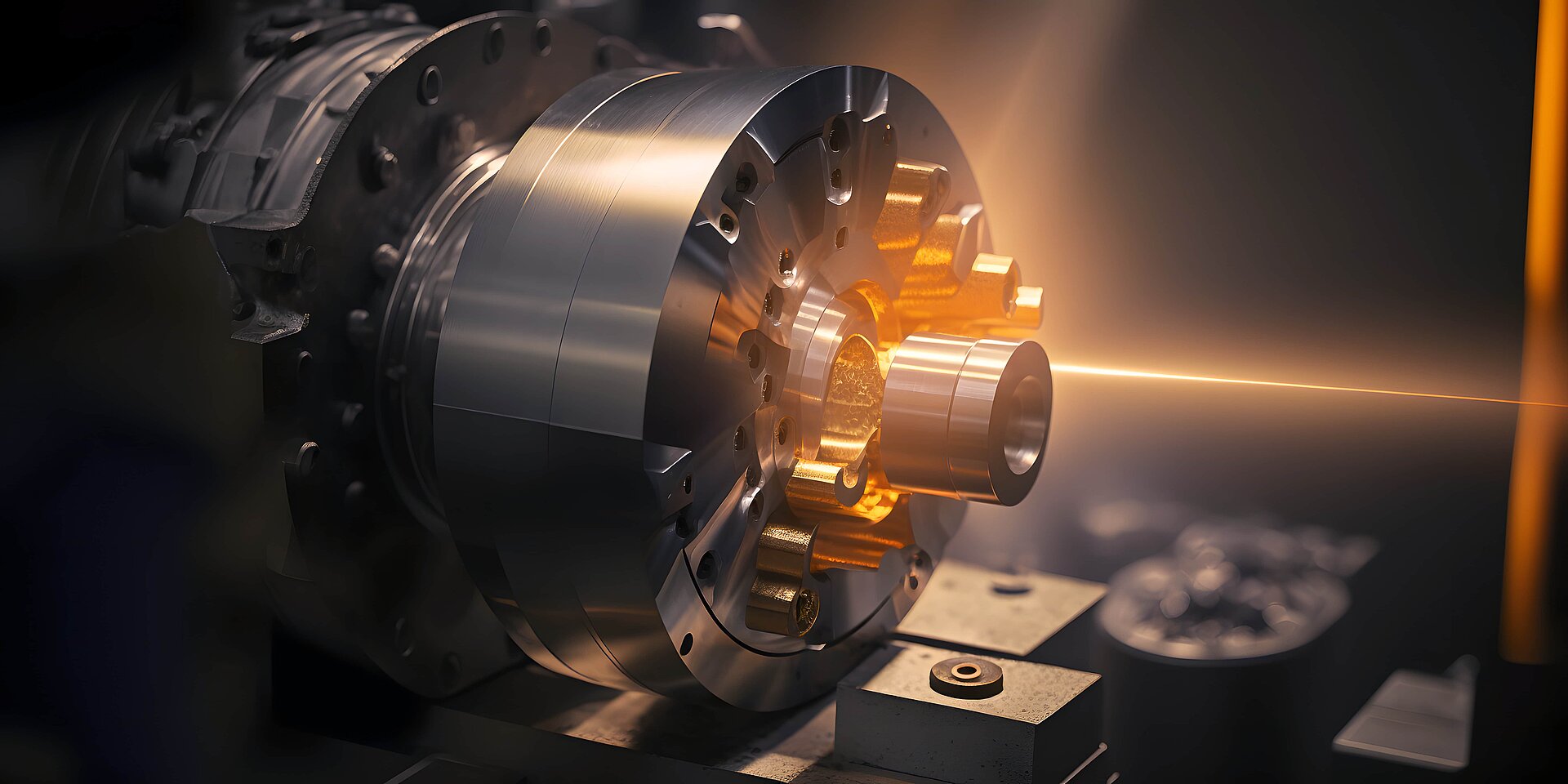

Machining Hard Materials

The advantage lies in the variety! That is why we offer CBN inserts for hard turning both as corner-tipped inserts and as solid inserts. If you combine the application possibilities of solid and corner-tipped inserts, new machining possibilities arise for hard turning, which enable faster machining with the best surface quality at the same time. Even more possibilities open up for you when our mixed ceramics are used as an alternative cutting material in hard turning.

Want to find out what solid and corner-tipped CBN inserts or our mixed ceramics can do for you?

Roll Machining

Our two grades of cutting material, ceramic and CBN, are ideal for roll turning and profiling. But we also have a lot to offer on the tooling side, from single, multi-bladed and multi-stage turning tools to tools with long overhangs for deep grooving, to make machining your rolls simpler and easier.

If you do not want to worry about the cutting thickness h and do not want to design the cutting alone - contact us!

Milling of HRSA Materials with Ceramic End Mills

Machining heat-resistant superalloys places high demands on tools, as heat, chip breaking and wear cause extreme stress on the tool cutting edge and place high demands on the cutting material. Our new white paper shows practical strategies for overcoming the challenges of milling Inconel & Co with ceramic end mills.

Contact Request

Are you interested in our machining solutions? We look forward to hearing from you!

Get in contactDigital Product Catalogue

Cutting materials, insert geometries and tools for your machining

Configure your individual cutting tool and request test samples. You will receive detailed product information and can also view the list price after your registration. This way you can quickly and easily request the desired product.

Success lies in the implementation of the machining task

When we talk to our customers, we hear again and again: I am not achieving my number of pieces in the shift because the tool life has collapsed. I am not achieving the required productivity with the cutting parameters of the tool used. Or the quality requirements are difficult to fulfil with the tool, so that the calculation for machining is no longer correct.

If such or similar problems occur, an identical insert made of a different cutting material is often simply used for machining. This is based on the assumption that the problem is solved. All other possibilities to improve the machining process are disregarded. This is where the machining experts from CeramTec come into play, who look at the entire machining process. Do chamfer design, insert geometry, cutting material fit the requirements? Do cutting parameters need to be adjusted, does the number of cutting passes need to be changed, or do special tools provide the solution? These are just a few measures from the spectrum of engineering that the CeramTec engineering team has in store - and on site at the customer, worldwide. Because the consideration of the most important influencing variables, as carried out by the CeramTec engineering team, brings the desired success in machining.

You need support with machining - simply fill out the contact form. We will get in touch with you.