Piezoceramics in the Automotive Industry

Piezoceramics are used in the automotive industry to manufacture high-precision sensors for various applications such as engine management, parking aids, fluid level sensing, accelerometers and tire pressure monitoring. Piezoceramics are characterized by the fact that they enable precise measurement and control to improve the performance and safety of vehicles.

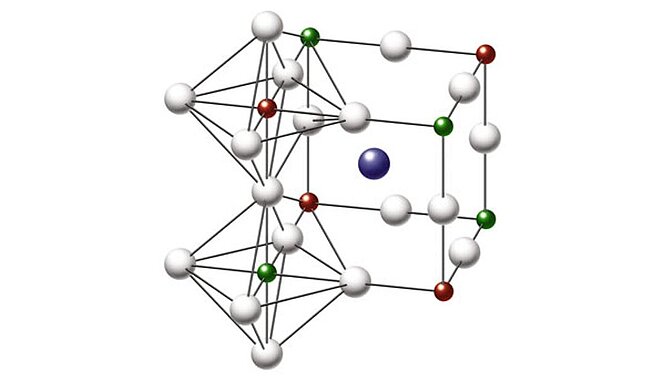

Are you looking for an alternative to lead-containing materials for your automotive application? Then find out about our lead-free piezoceramic solutions based on BNT-BT.

Power Transducers

Sensor Technology

- Wheel balancers

- Energy harvesting for tire pressure sensors

- Knock sensors

- Level Sensors (oil & fuel)

- Parking distance control (PDC sensors)

In this application the piezoceramic resonates at a high frequency, depending on the design, between of 1 MHz and 3 MHz. The piezo part is incorporated into an integrated circuit board which is part of the sensor. The sensor itself is mechanically coupled to the bottom of the oil tank in the car. The piezo works first as a transmitter and creates an ultrasonic wave into the liquid. The ultrasonic wave travels through the liquid and is reflected by the surface. The piezo transducer switches to receiving mode and creates an electrical signal once the reflected wave hits the surface of the sensor. By measuring the traveling time of the ultrasonic wave between sending and receiving of the signal, the distance between the bottom of the oil tank and the surface of the oil can be calculated. By this intelligent system, on-board diagnosis in the car is possible. It replaces the old fashioned mechanical method with an oil level gauge.

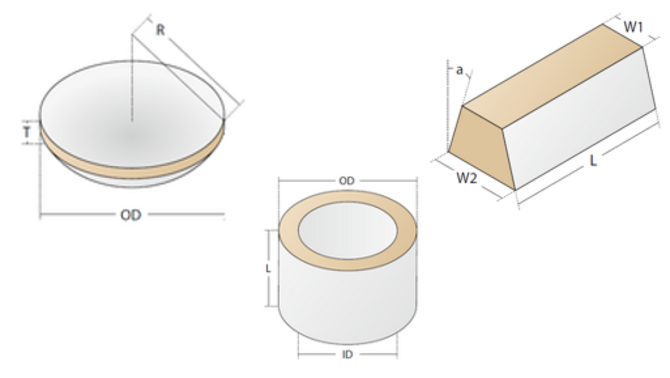

Designs: Round disc.

A piezoceramic sensor plate transforms dynamic pressure fluctuations into electrical signals, which can then be processed accordingly. The pressure fluctuation is generated by a seismic mass coupled to the piezoceramic part, which applies force to the piezoceramic disc when the entire system is accelerated. This system is used for example in dynamic wheel balancing machines where every imbalance in the wheel generates a signal in the piezoceramic part. It is then possible to detect and quantify any imbalance in car wheels within seconds and to position appropriate counterweights.

Designs: Round disc, rectangular plate, ring

A knock sensor consists of a piezoceramic ring, a seismic mass and contact electrodes. The complete unit is attached to the engine block at an appropriate location. The engine vibrations accelerate the knock sensor and the seismic mass generates a force on the piezoceramic ring. The ring then generates an electrical signal equivalent to the vibrations in a wide frequency range. If the engine starts to “knock” due to lower octane gasoline or changing operating conditions, the signal is detected by the evaluation electronics and the ignition map is readjusted accordingly. This intelligent engine management allows combustion to take place very close to the knocking limit, which lowers fuel consumption.

Designs: Ring, round disc

A piezoceramic transducer emits a short ultrasonic pulse, which is reflected by an obstacle before being received again by the same piezo transducer. The wave propagation time is used for calculating the distance to the obstacle. Sensors of this kind are used for example in trucks for exact detection of the distance to the loading ramp when the driver is reversing, or as parking aids in passenger cars.

Designs: Round disc, in part with wrap-around metalization