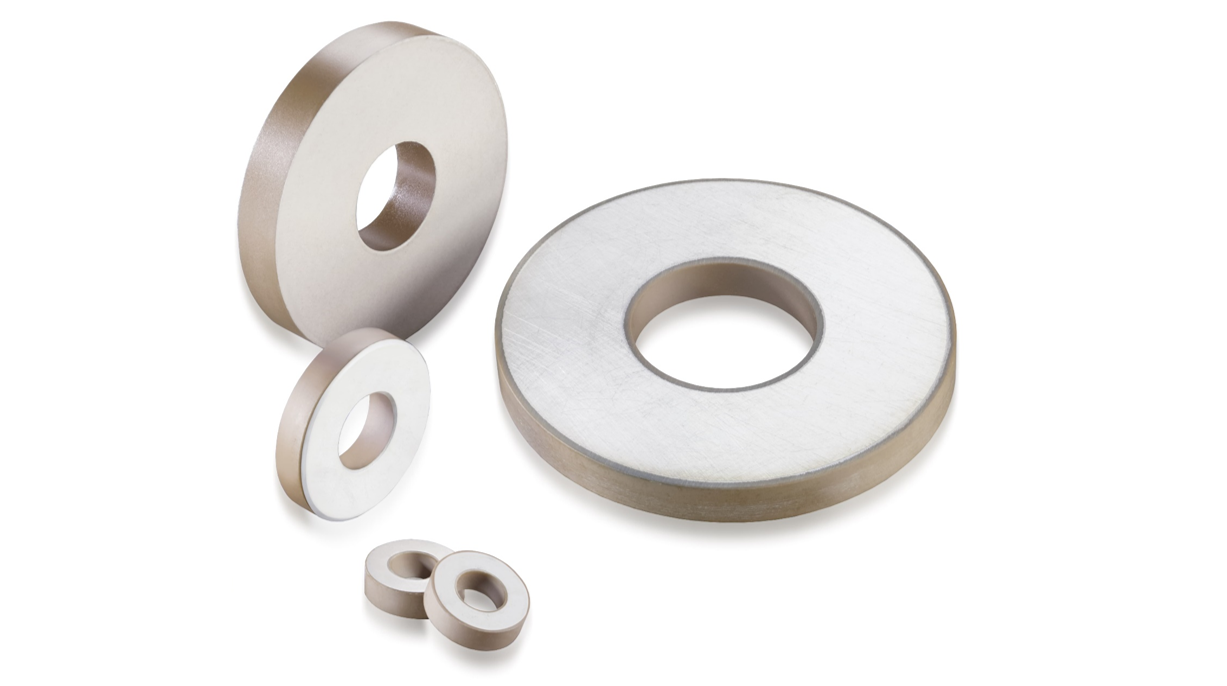

Dimensional Range

- Outside Diameter from 2mm (0.08”) to 150mm (5.9”)

- Inside Diameter from 1mm (0.04”) to 140mm (5.5”)

- Thickness from 0.15mm (0.006”) to 25mm (1”)

Custom sizes dimensions outside of the above may be possible – please consult for further information.

Standard Mechanical Tolerances

- Outside Diameter ± 0.150mm

- Inside Diameter ± 0.150mm

- Thickness ± 0.05mm

- Flatness 0.002**/0.012mm MAX (** lapped silver or sputtered)

- Parallelism 0.007**/0.012mm MAX (** lapped silver or sputtered)

- Concentricity 0.2mm

Tighter mechanical tolerances are achievable but are dependent on the geometry.

Metallisation Type

- Silver fired thick film standard - Silver fired thick film flat lapped

- Electroless nickel - Gold flash

- Tin - Evaporated Gold, Nickel and others available on request

Typical Impedance Responce Trace (Radial Resonance)

The above is a typical impedance trace measured on a dedicated analyser and depicting the resonance and anti-resonance points associated with the ring shaped component. This data allows the calculation of piezoelectric activity and other important characteristics required for the application.