Applications include

- Acceleration sensors

- Level sensors (oil & fuel)

- Parking distance control

- Flow rate measurement (water & heat metering)

- Liquid and gas flow sensors

- Micro-pump actuators

- Non-destructive material testing

- Ultrasonic cleaning

- Ultrasonic distance sensors & ultrasonic counters

- Ultrasonic nebulizers

- Sonar technology & hydroacoustics

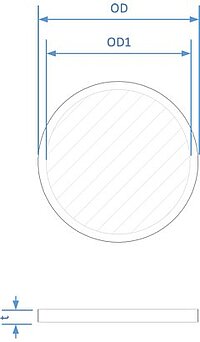

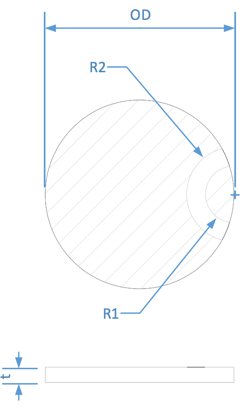

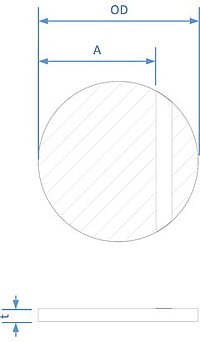

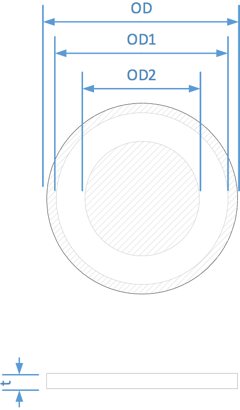

Dimensional Range

- Diameter from 3mm (0.12”) to 254mm (10”)

- Thickness from 0.08mm (0.003”) to 25.4mm (1”)

Custom sizes dimensions outside of the above may be possible – please consult for further information.

Standard Mechanical Tolerances

- Diameter ± 0.150mm

- Thickness ± 0.05mm

Tighter mechanical tolerances are achievable but are dependent on the disc diameter and thickness.

Metallisation Type

- Standard metallisation: Silver fired thick film

- Evaporated nickel

- Electroless nickel - Gold flash

- Gold over Nichrome - Evaporating (others available on request)