Technical 3Y-TZP Cutters for the Textiles Industry

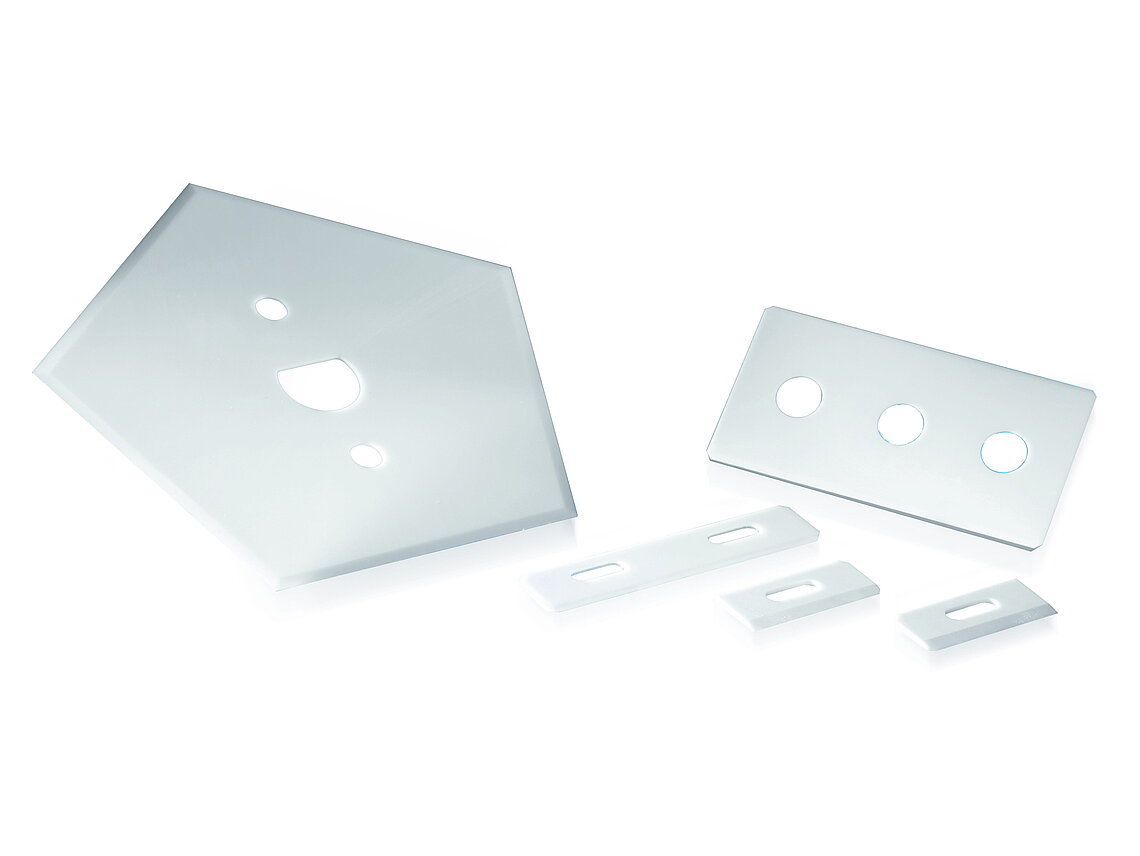

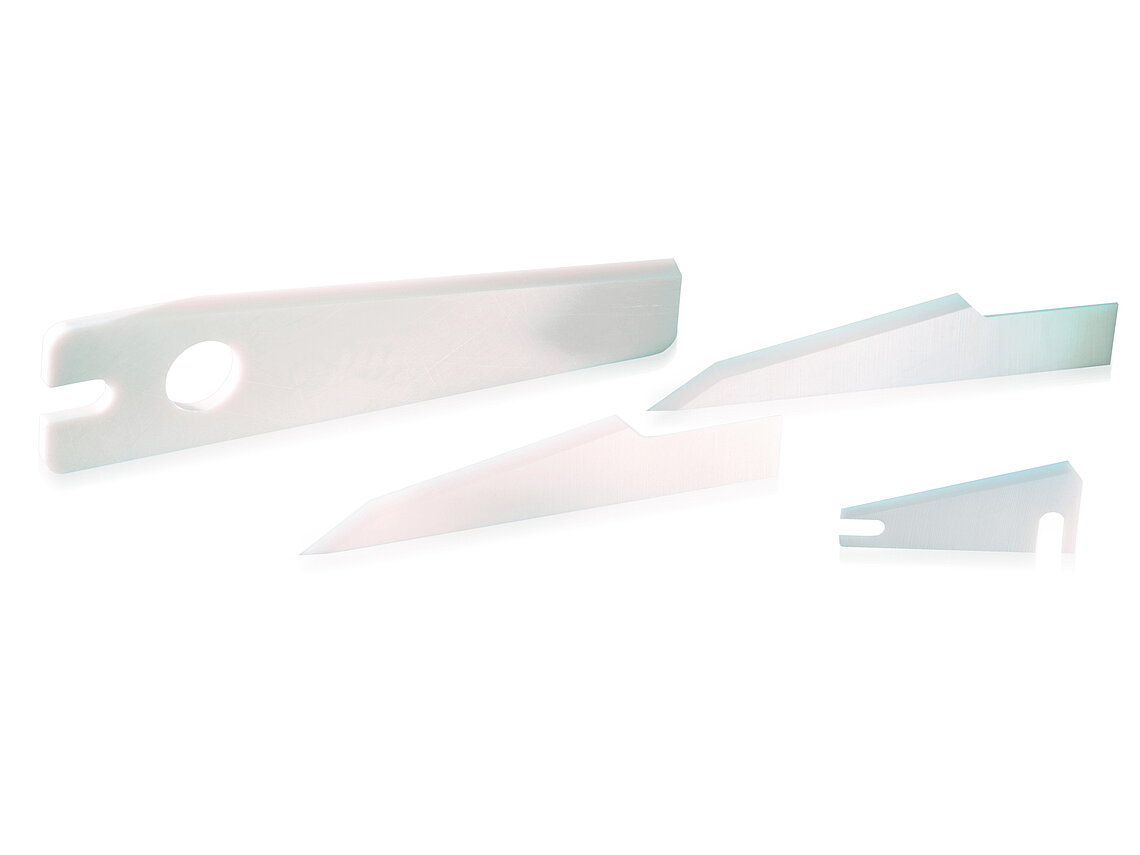

High endurance, consistently neat cuts, no fiber-pinching or backlashing of fiber within the cutting angle zone of the shears – these are just a few of the many benefits of using zirconium oxide cutters in the production process.

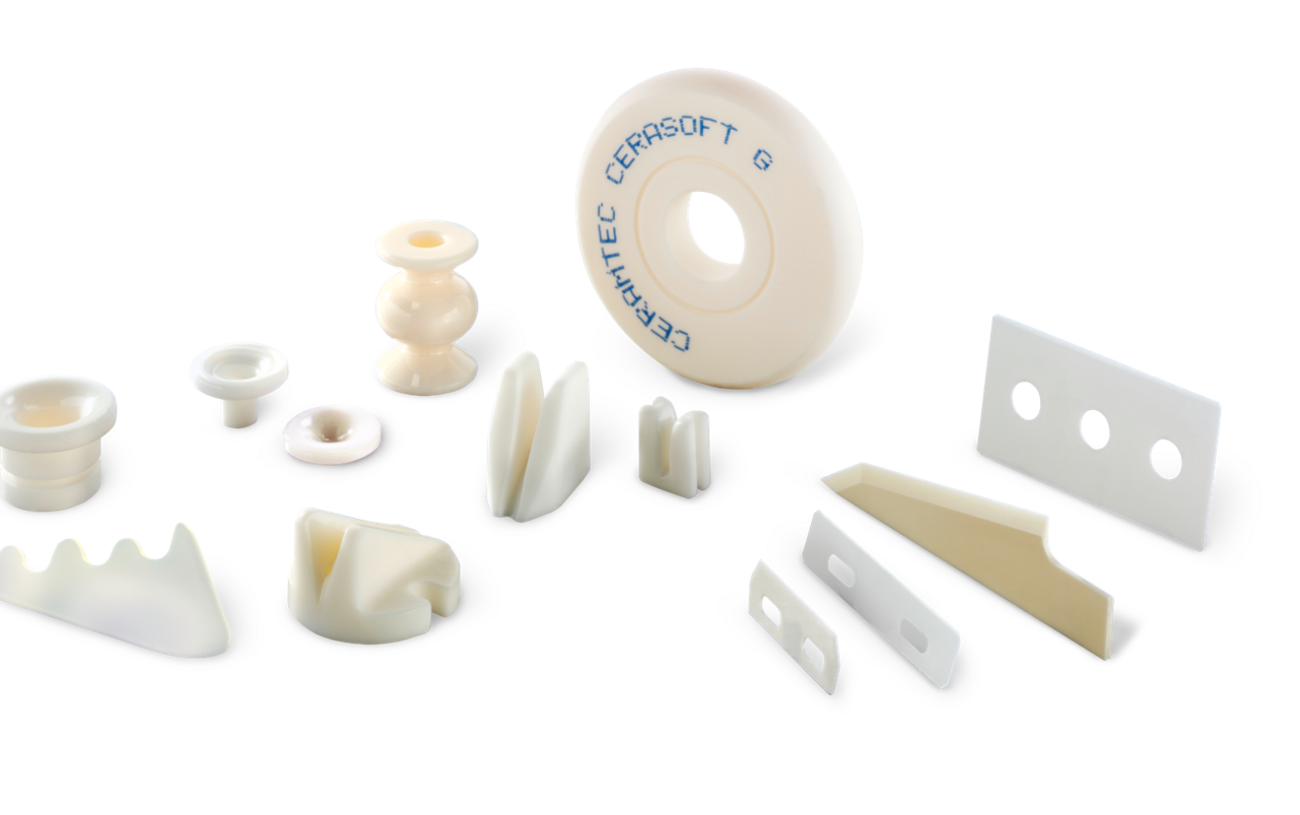

CeramTec has developed a high-performance yttrium-reinforced zirconium oxide ceramic (TZP) for cutting yarns and textiles. It stands out from other materials with its extremely high cutting edge strength and excellent flexural strength and hardness. The use of 3Y-TZP cutters improves efficiency in cutting textile threads, which ultimately increases profitability.

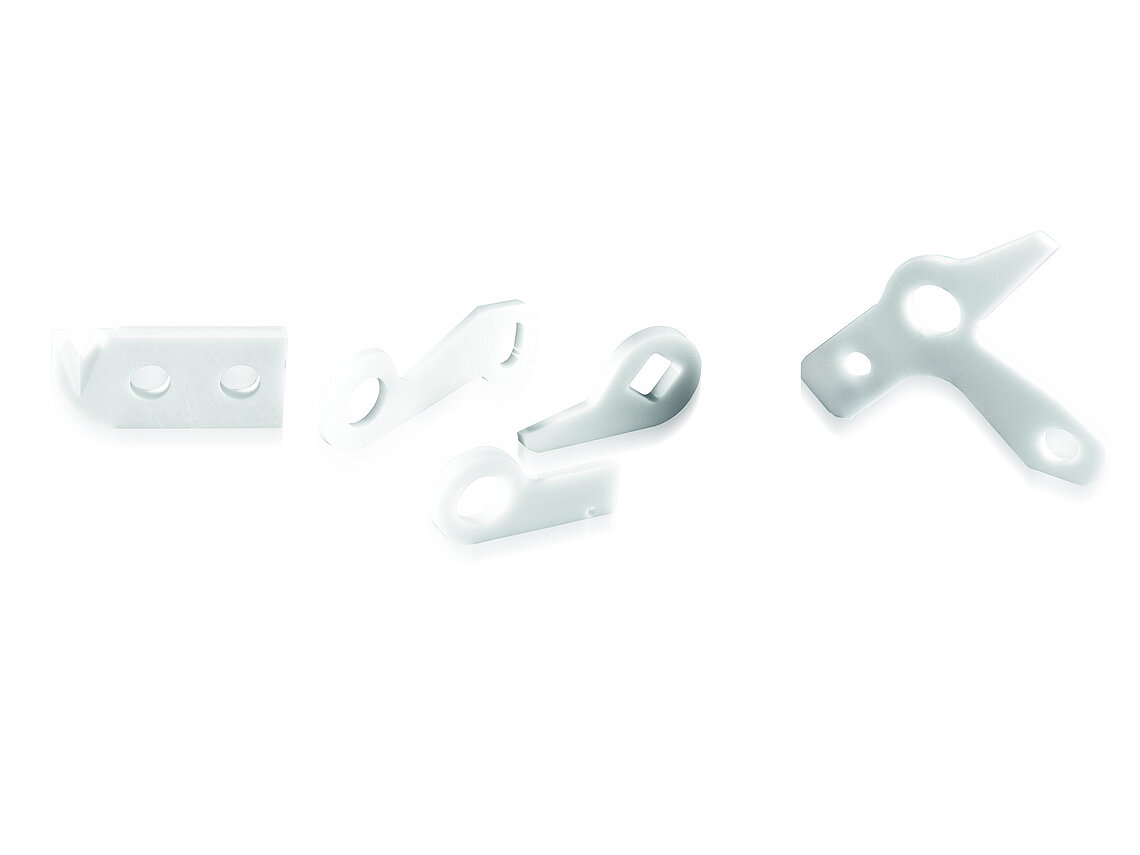

The number of applications in the textile industry ranges from splicers, suction tube and residual thread cutters for winding machines, to end thread and diagonal cutters for looms. Technical cutters made of reinforced zirconium oxide ceramics are the standard material of choice in many machines and applications.

Expanding Areas of Application for Ceramic Cutters

The range of applications for these ceramic cutters is always expanding. In addition to their use in the textile industry, 3Y-TZP cutters are already used as shears, blades or knives in these industries as well:

- Automotive

- Food and beverage production

- Medicine

- Packaging industry