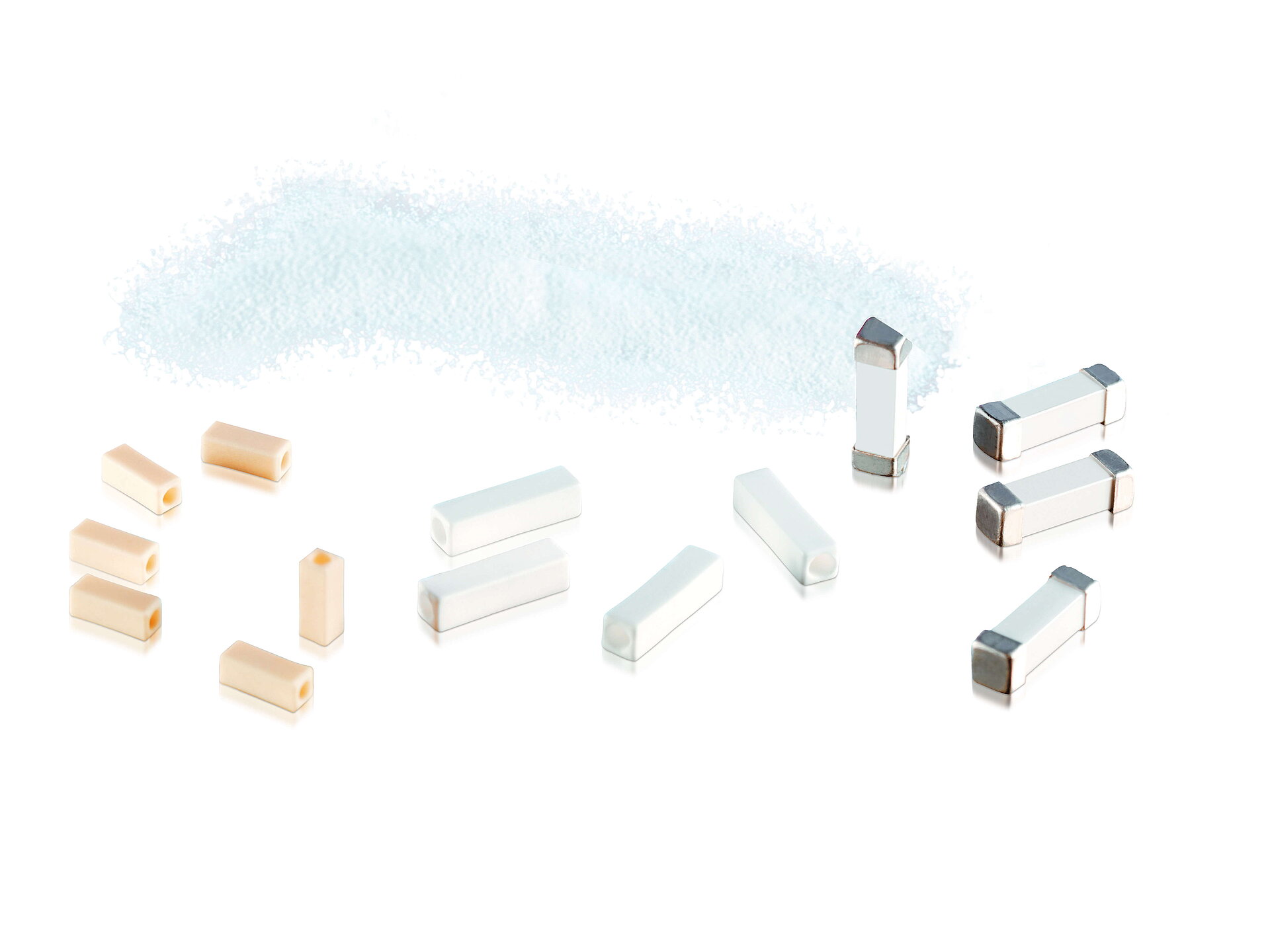

Silicate Ceramic Elements and Ziralit for Circuit Breaker Design

Insulation is a central element in circuit breaker technology. Silicate ceramic elements and Ziralit offer additional properties and advantages indispensable to electrical circuit breakers.

Naturally, insulation is the most important element here, but other properties such as high strength and form stability, resistance to aging, insensitivity to chemical influences and corrosion, tracking resistance as well as resistance to temperature changes and heat are all among the many features of CeramTec circuit breaker components made from silicate ceramics.

This results in a number of advantages customers won’t want to miss: Ceramic components extend the technical service life of fuses, increase safety, allow shorter disconnect times and ensure more cost-efficient design.

Ziralit is a zirconium oxide toughened alumina with many advantages in circuit breaker technology – especially in telecommunications:

- Excellent flexural and dielectric strength

- Outstanding temperature resistance

- Superior toughness

- Enhanced performance for large-scale production and tight tolerances

Due to its high temperature performance, the material offers tremendous advantages over standard silicate ceramic parts for fuses in the field of telecommunications, where highly demanding requirements of 600V and 60A are not uncommon.