Impact Sensors

Our impact sensors use Piezoceramic material to detect and measure impact forces in applications as varied as coin validation and testing hardness.

Detect and Measure Impact

Togehter with our customers we optimise our impact sensors for consistency of response in a variety of conditions (angle of impact, temperature etc).

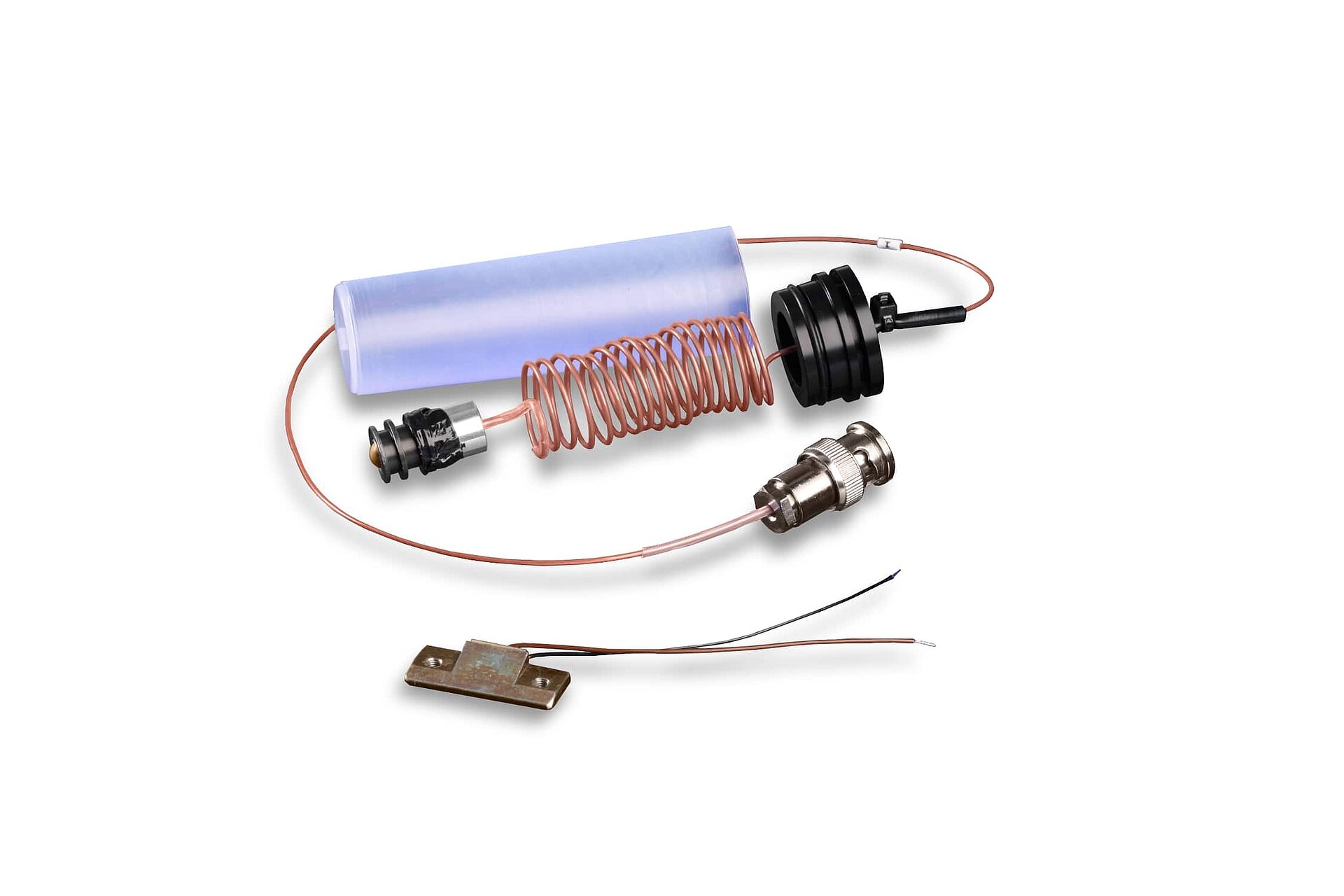

Bespoke Impact Sensor

Complex assemblies are designed and developed using 3D solid modelling software and FEA software for fast and accurate detailed designs.

Accelerometers

The Technical Ceramics business of CeramTec provides piezo materials that are ideal for use in accelerometers for the measurement of vibration in aerospace applications, due to their excellent stability and high sensitivity.

They can be used in compression or shear mode to form single or multi-axis accelerometers, with standard housings or customer-designed packages.

For even higher levels of sensitivity, we have a range of bimorph materials is available.

Wheel / Rotor Balancing Sensors

Providing dynamic force measurement in automotive or industrial applications, our standard sensors offer easy installation, excellent quality and reliability.

Manufacturing sensors for dynamic force measurement, our standard sensor is used in the automotive industry in wheel balancing equipment, but also in applications such as measuring the force exerted on the brake pedal during brake tests.

For that reason the sensor is available in a number of versions for easy installation in different devices. It can be supplied with exposed (solderable) connectors or with customised cables and connectors.

Dynamic force measurement sensors include 2 over-moulded sensing elements (PZT5A2 Navy type I or PZT4 navy type II) and polypropylene material used for over-moulding. The active materials allow the application of load up to 60 MPa whilst the polypropylene used for over-moulding PZT and contact elements does not present stress-cracking problems and offers excellent chemical and humidity resistance.

Features of wheel/rotor balancing sensors include:

- Watertight IP rated connectors

- Oil, chemical and solvent resistant cables that are perfect for harsh environment or garage workshops

- Easy installation

- Humidity resistance

- Max load of 60MPa

We provide a number of wheel/rotor balancing sensor versions available with or without cables and a connector, which enables us to offer an easily installed and convenient solution based on your requirements.

Whether it is a standard sensor, or a custom sensor built to your specifications, our entirely traceable manufacturing processes ensure quality and reliability in low, medium and high volumes.

If you are interested in utilising our wheel/rotor balance sensors, or would like to find out more about how they can be used in a range of different automotive or industrial applications, contact us today.