Machining of Heat Resistant Super Alloys

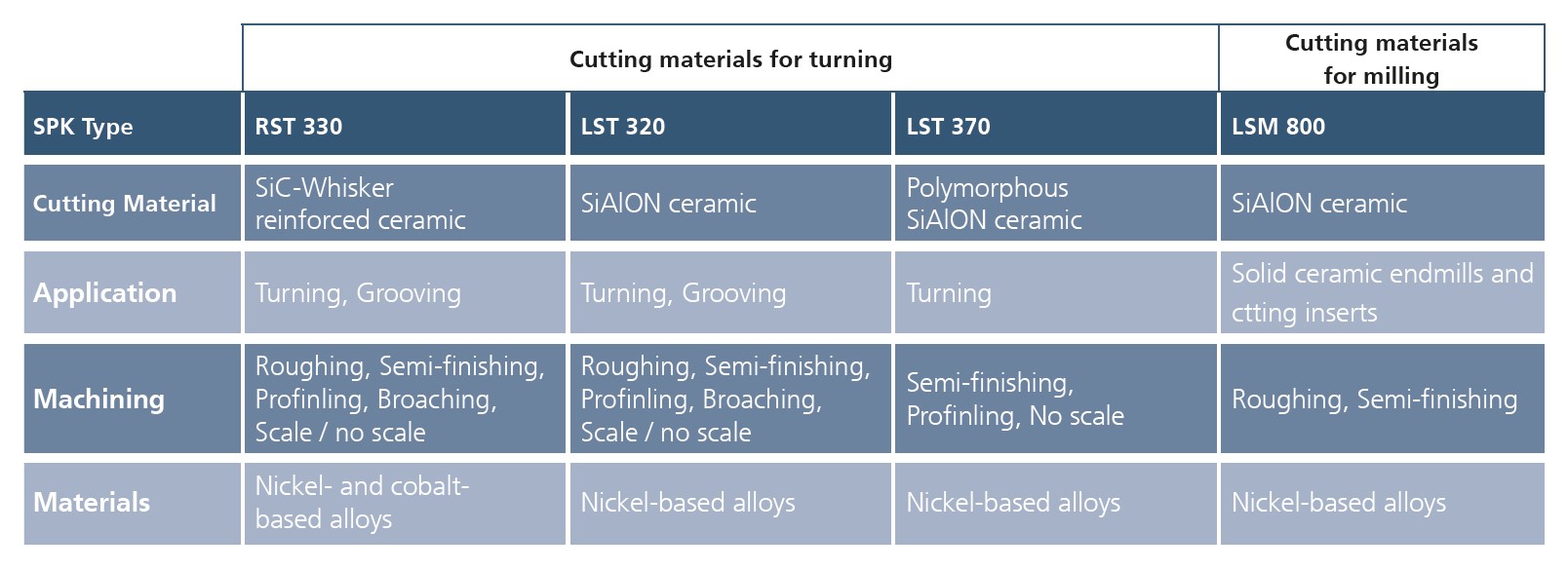

Ceramic cutting materials and whisker ceramics are our successful duo for machining HRSA materials. The focus is on turning, grooving and milling for roughing and semi-finishing applications. With our ceramic grades for turning LST 320, LST 370 and our whisker ceramic grade RST 330, as well as our LSM 800 grade for milling, you can easily and quickly machine your nickel-based alloy and cobalt-based alloy components with our top grades. Look at the performance of our cutting materials now.

Milling of HRSA Materials with Ceramic End Mills

Machining heat-resistant superalloys places high demands on tools, as heat, chip breaking and wear cause extreme stress on the tool cutting edge and place high demands on the cutting material. Our new white paper shows practical strategies for overcoming the challenges of milling Inconel & Co with ceramic end mills.

HPC - High Pressure Coolant Tooling System

The special feature of our HPC tooling system is that the coolant is supplied through the clamping finger. The coolant outlets on the finger are designed to deliver coolant directly to the active zone where it is needed. A coolant pressure of up to 200 bar can be applied to the tool.

Another advantage of high-pressure cooling is that the chip can be broken into small pieces. This eliminates process-disturbing ribbon chip.

Tool System for High-Performance Machining

Our ICT tool system shows its strengths when process reliability is an important criterion for you when turning HRSA materials. We offer it with and without high-pressure cooling. As a high-pressure tool, the cooling lubricant reaches the effective zone directly and at the same time ensures reliable chip breaking.

Special Tools

The machining task you are facing cannot be solved with standard tools? No problem. Our engineering team will develop the tool that solves the task for you. No matter whether the machining task requires a special insert geometry or a special tool shape.

The tool is then manufactured as quickly as possible in our own production facility in Germany.

Contact Request

You have a machining task that you want us to solve? Great! Let us know: Where can we support you?

Contact usDigital Product Catalogue

Cutting materials, insert geometries and tools for your machining

Configure your individual cutting tool and request test samples. You will receive detailed product information and can also view the list price after your registration. This way you can quickly and easily request the desired product.