Piezoelectric Plates & Bars

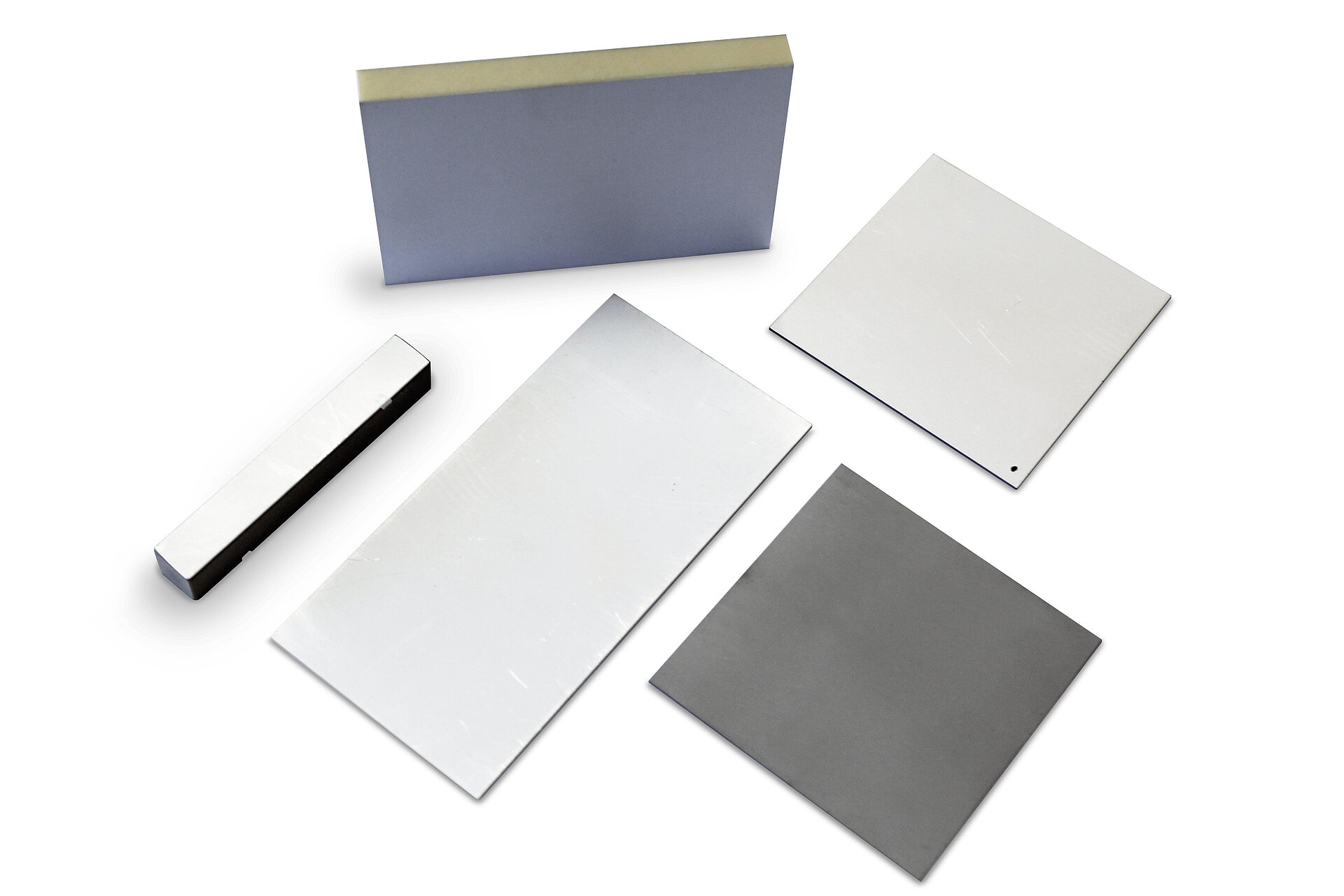

CeramTec is a leader in the design and manufacture of complex electronic ceramic components and assemblies used in a wide range of applications and cutting edge technologies. CeramTec Industrial specialises in the development and production of piezoceramic plates and bars, for which a wide range of metallisation variants is possible.

Applications include

- 1-3 Composites for SONAR and medical imaging

- Linear ultrasonic motors

- Megasonic cleaning

- Non-destructive material testing

- Pressure sensors

- Sonar technology & hydroacoustics

- Tactile feedback (haptics)

- Ultrasonic sensors

CeramTec manufactures piezoelectric ceramic blocks designed for use in ultra-low SONAR applications up to 18KHz. These blocks (Navy II material standard) offer excellent electrical characteristics, exhibit high sintering density and are available in nine high-sensitivity piezoceramic formulations suitable for the fabrication of wide bandwidth composite transducers (1-3 composites). However, the most striking feature of the PZT ceramic blocks is their size and especially their thickness, which is currently a maximum of 48 mm.

Dimensional Range

- Length from 0.25mm (0.01”) to 165mm (6.5”)

- Width from 0.25mm (0.01”) to 165mm (6.5”)

- Thickness from 0.15mm (0.006”) to 48mm (1.9”)

Custom sizes dimensions outside of the above may be possible – please consult for further information.

Standard Mechanical Tolerances

- Length & Width ± 0.150mm

- Thickness ± 0.05mm

- Squareness (edge to face): Within 0.15°

- Flatness (lapped parts): 0.012mm (lapped), 0.015mm (sliced)

- Parallelism: 0.012mm (lapped), 0.06mm (sliced)

Tighter mechanical tolerances are achievable but are dependent on the plate length, width and thickness.

Metallisation Type

- Silver fired thick film

- Evaporated nickel

- Electroless nickel - Gold flash

- Tin - Evaporated Gold and others available on request