IAA: CeramTec is presenting its cooling solution for a power module

Visionary concept vehicles, electric mobility, alternative drives - these are the topics of the IAA in Munich. CeramTec, the world's leading manufacturer of technical advanced ceramics, will be part of this theme world. To accompany the IAA, CeramTec is presenting its recently developed ceramic cooling solution for a power module that is used in inverters in the drive trains of electric cars. This is because the power electronics in e-mobility require innovative cooling solutions that function safely and reliably in the smallest spaces. Cooling solutions from CeramTec can make a decisive contribution here.

Electromobility is making massive inroads. However, the automotive industry is facing challenges in the further development of powertrains, including limited installation space, increasing performance requirements and the demand for long ranges. Thanks to new materials, semiconductor chips are achieving ever higher power densities, but this also generates more heat. To still be able to implement performance increases, it is necessary to lower thermal resistances. CeramTec has risen to this challenge and developed a pioneering cooling solution for the power electronics in electric cars. It helps to ensure that the regulation and control in electromobility function safely and reliably.

Ceramic heat sinks for innovative e-mobility solutions

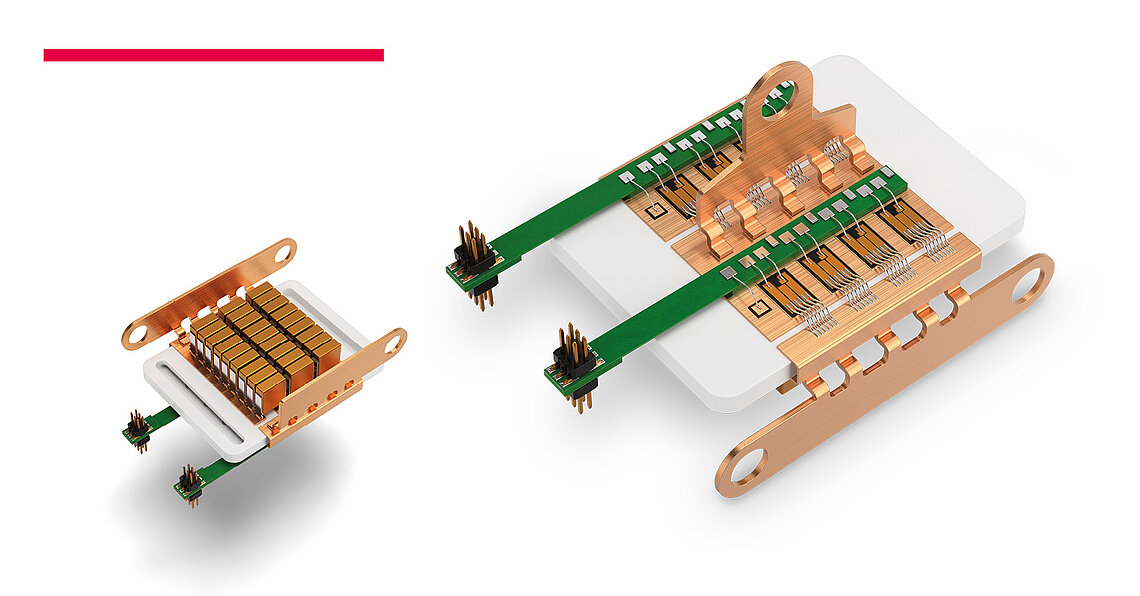

High-performance ceramics are particularly suitable for deheating SiC semiconductor chips, for example, as they offer high thermal conductivity, electrical insulation and resistance to corrosion and wear. Particularly high power densities are achieved with liquid coolers. Unlike air, water or glycol mixtures achieve a significantly higher cooling capacity. To ensure efficient heat dissipation, the new generation of ceramic cooling systems uses chip-on-heatsink technology to attach the chip directly to the metallised ceramic heat sink. In this way, it is particularly close to the cooling liquid. To achieve this, the structured copper sheets are applied directly to the front and back of the ceramic cooler. By means of this structure, it is also possible to use both sides as circuit carriers and to cool them simultaneously.

The inner cooling structure of the ceramic is designed as a pin-fin structure. This significantly increases the heat transfer surface of the heat sink and enables ideal circulation around the pin-fin surface. In this way, heat is optimally dissipated and at the same time the structure increases the mechanical strength, which can thus absorb pressure, torsion and bending forces well.

Compared to conventionally constructed systems, the thermal resistance of chip-on-heatsink heat sinks is only half the value. The very compact heat sink measures only 48 x 36 mm is 3.6 mm thick (including metallisation) and weighs ten grams. Based on the thermal characterisation, the performance of the module was impressively confirmed in the PowerCycling test. The thermal resistance of the power module with Pin-Fin ceramic cooler is 0.15 K*cm²/W at the design point from the chip to the cooling water.

Discover more information about CeramTec cooling technology