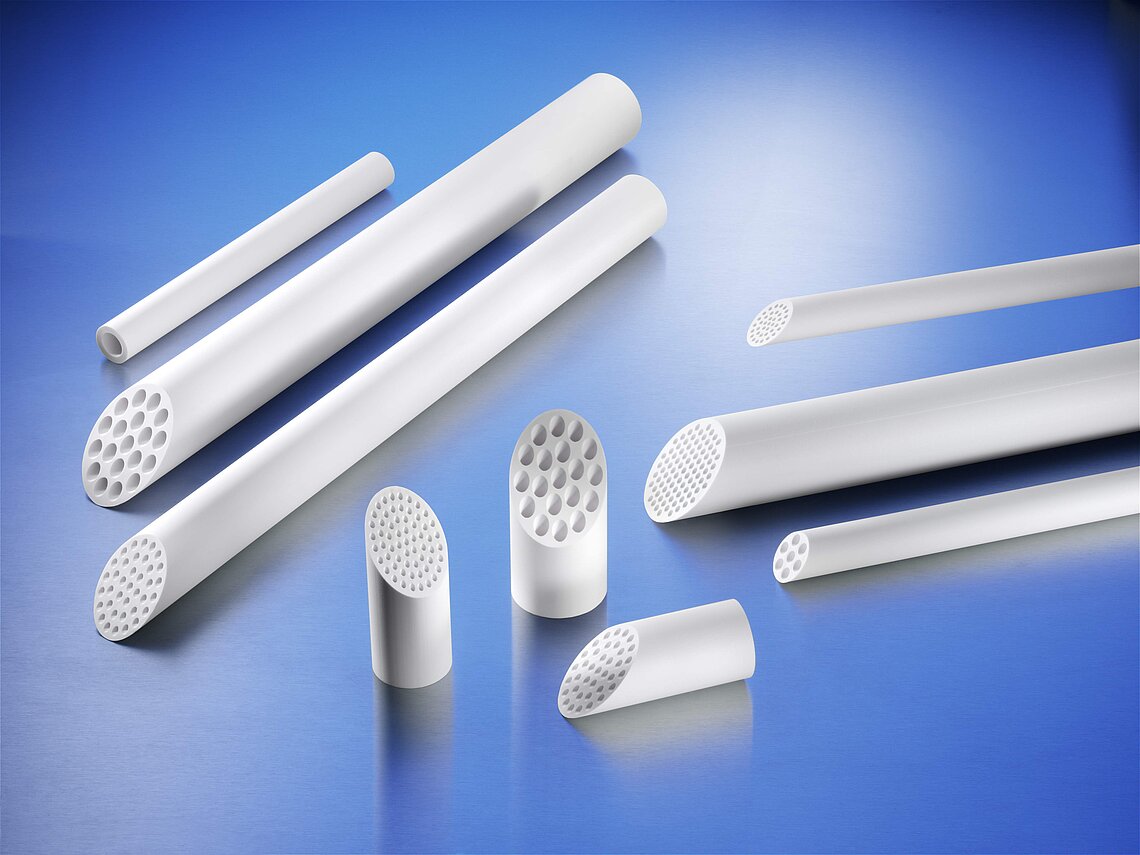

CeramTec’s ceramic multi-channel tubes for liquid filtration

High-quality industrial materials are essential for cost-efficient filtration processes. CeramTec’s porous ceramic membrane tubes that are used for cross-flow membrane filtration combine key properties that provide customers with enhanced performance and ultimately save cost on filtration units.

Made from alumina (Al2O3), the multi-channel tubes are designed for nano-, ultra-, and micro-filtration in a range of industries to separate substances and solids from liquids, including food and beverage, pharmaceutical, chemical, electroplating, environmental technology and biotechnology. Both with regard to the number of channels and length of tube, the product provides the maximum performance that technology currently allows: The ceramic multi-channel element as the supporting tube onto which the separation layer is mounted consists of up to 85 channels with lengths of up to 1.5m.

“We know from our clients, who use our tubes for the installation of filtration units, that these properties can deliver significant benefits as longer tubes provide a bigger filtration area which is key for the performance capability of a filter. The longer the tubes, the fewer tubing and peripheral equipment is needed client-side to get the same filter performance. The same applies to the amount of tubes, i.e., the more tubes, the bigger the filtration area and the more efficient the filter facility,” says Stephanie Neuberger, Account Manager at CeramTec. “Ceramic membranes are increasingly used to improve filter performance and we’re therefore constantly looking to develop our product in line with market requirements. At the moment, we’re working on increasing the amount of tubes even further to enhance our offering and push the boundaries of what can be done in the liquid filtration space.”

Compared with polymeric membranes or sintered metals, ceramic membranes exhibit better mechanical strength, thermal stability and chemical compatibility, which makes them ideal for filtration processes under harsh conditions, such as high pressure and high temperature. They are highly inert, have a high permeate flux rate and can easily be backflushed to clean build up on the surface. The CeramTec Al2O3 material has a medium porous channel with a diameter of approx. 8 μm and a porosity of 28%. Typical tube lengths are between 1m and 1.5m, the typical outside diameter is between 10 mm and 52 mm and the typical channel diameter is between 2mm and 16mm.