Piezoelectric Tubes

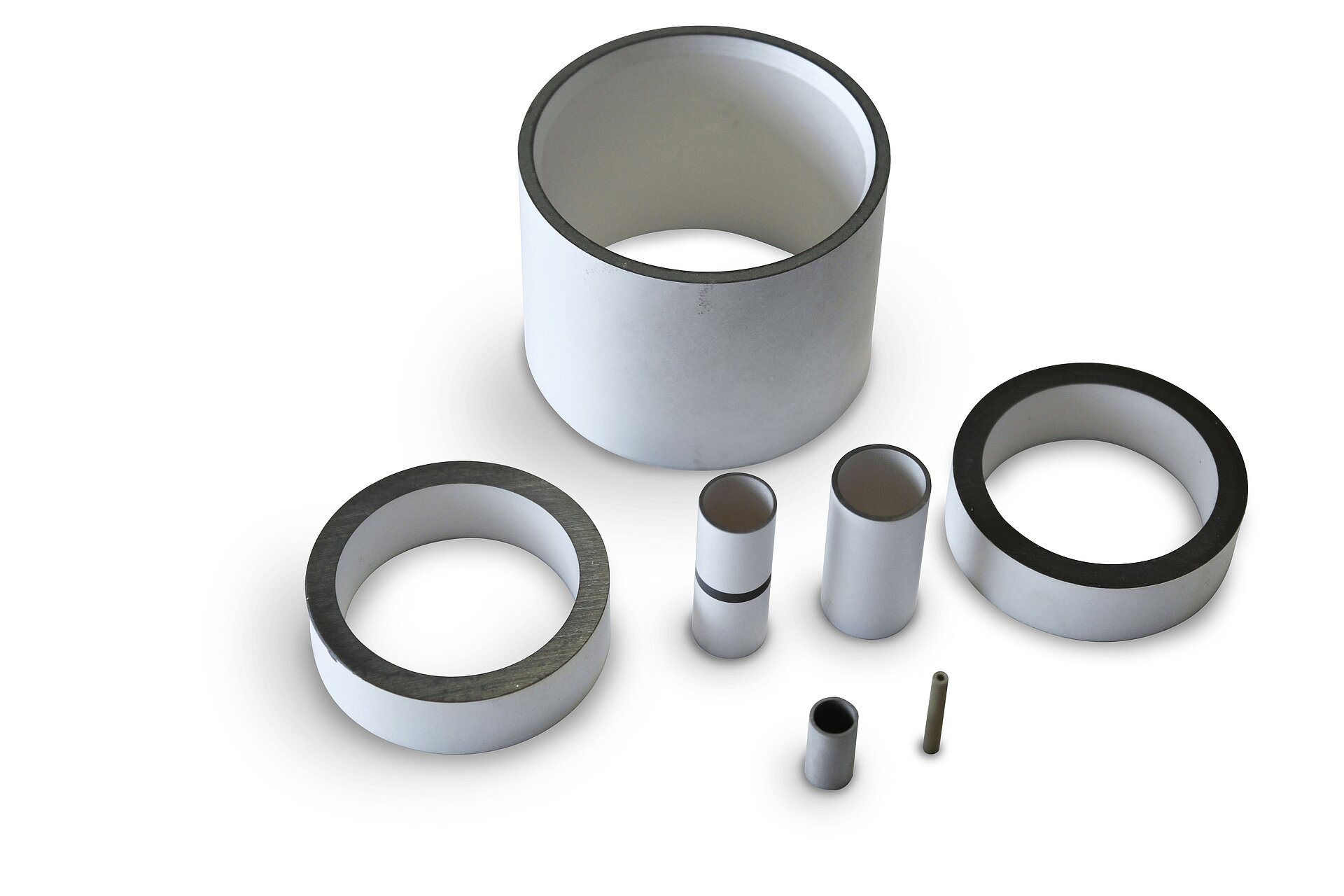

CeramTec is a leader in the design and manufacture of complex electronic ceramic components and assemblies used in a wide range of applications and cutting edge technologies. CeramTec’s Global Electroceramics Division specialises in the development and production of various tubes sizes, bearing variety of electrode and metallisation configurations.

This variety of tubes is fabricated from 33 published and additional custom in-house piezoelectric material formulations to address needs such as high power, sensitivity, stability in cryogenic temperatures as also in high temperatures and extreme pressure imposing applications.

Applications include

- Acceleration sensors

- Augmented reality

- Fibre optic stretcher

- Hydrophones

- Micro dispensing

- Oil and gas exploration

- Pressure sensors

- Print head transducers

- Scientific equipment

- Sonar technology & hydroacoustics

- Ultrasonic wind speed measurement

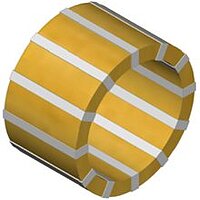

CeramTec offers a wide range of striped tubes for the defence sector with an innovative design, offering lower frequency and increased drive for applications where high acoustic transmitting properties are required. The striped tubes can achieve typical frequencies of 12–15 kHz for a two inch tube and guarantee higher, stronger acoustic signals underwater. In contrast to a standard tube, which has three main resonance modes (length, wall and circumferential), striped tubes have one main resonance – the circumferential mode.

Dimensional Range

- Outside Diameter - from 2mm (0.08”) to 150mm (5.9”)

- Inside Diameter - from 1mm (0.04”) to 140mm (5.5”)

- Length - from 1mm (0.04”) to 150mm (5.9”)

Parts can be produced to the size ranges shown, but not in every combination of dimensions expressed above.

Standard Mechanical Tolerances

- Outside Diameter ±0.150mm

- Inside Diameter ±0.150mm

- Length ±0.05mm

Tighter mechanical tolerances are achievable but are dependent on the inside and outside diameters as well as length.

Metallisation Type

- Silver fired thick film - Evaporated Nickel

- Electroless nickel - Gold flash

- Tin - Evaporated Gold and others available on request