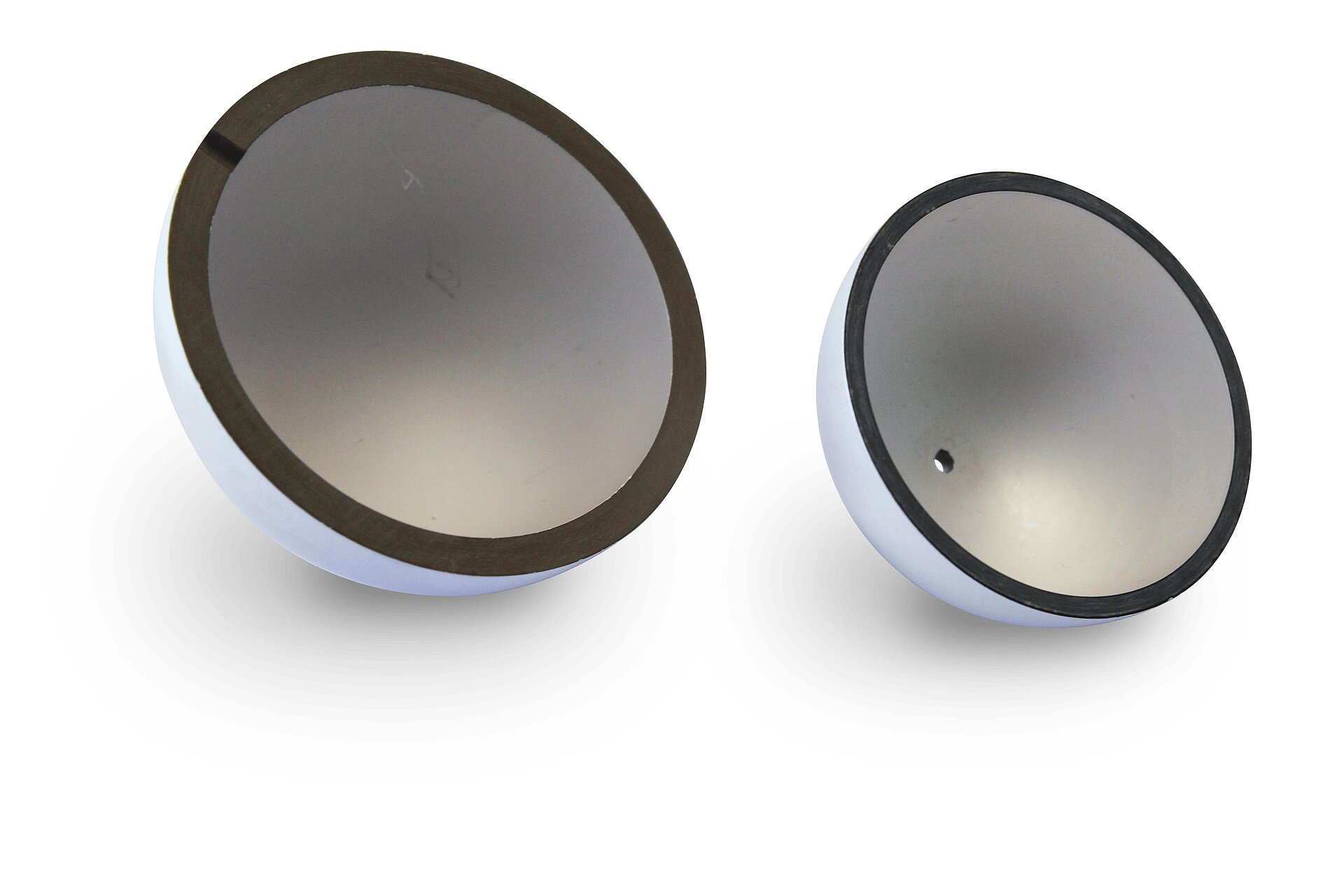

Piezoelectric Hemispheres

CeramTec is a leader in the design and manufacture of complex electronic ceramic components and assemblies used in a wide range of applications and cutting edge technologies. CeramTec Industrial specialises in the development and production of various hemispherical segments and focal bowls with different electrode and metallisation configurations.

Applications include

- HIFU medical and industrial

- Hydrophones

- Sonar technology & hydroacoustics

- Underwater object recognition

Features

- Choice of metallisation (Silver, Nickel, Gold and others)

- Evaporated and chemically deposited metallisation's available

- Thickness frequency tuning available on request

- Wide choice of PZT formulations

Dimensional Range (Hemisphere/ focal bowl)

- Outside Diameter/ Diameter from 6mm (0.24”) to 152.4mm (6”)

- Wall thickness / Thickness from 1mm (0.04”) to 10mm (0.39”)

Custom sizes dimensions outside of the above may be possible – please consult for further information.

Standard Mechanical Tolerances

- Outside diameter/ diameter ± 0.150mm

- Wall thickness / Thickness ± 0.05mm

Tighter mechanical tolerances are achievable but are dependent on the plate length, width and thickness.

Metallisation Type

- Silver fired thick film - Evaporated Nickel

- Electroless nickel - Gold flash

- Tin - Evaporated Gold and others available on request