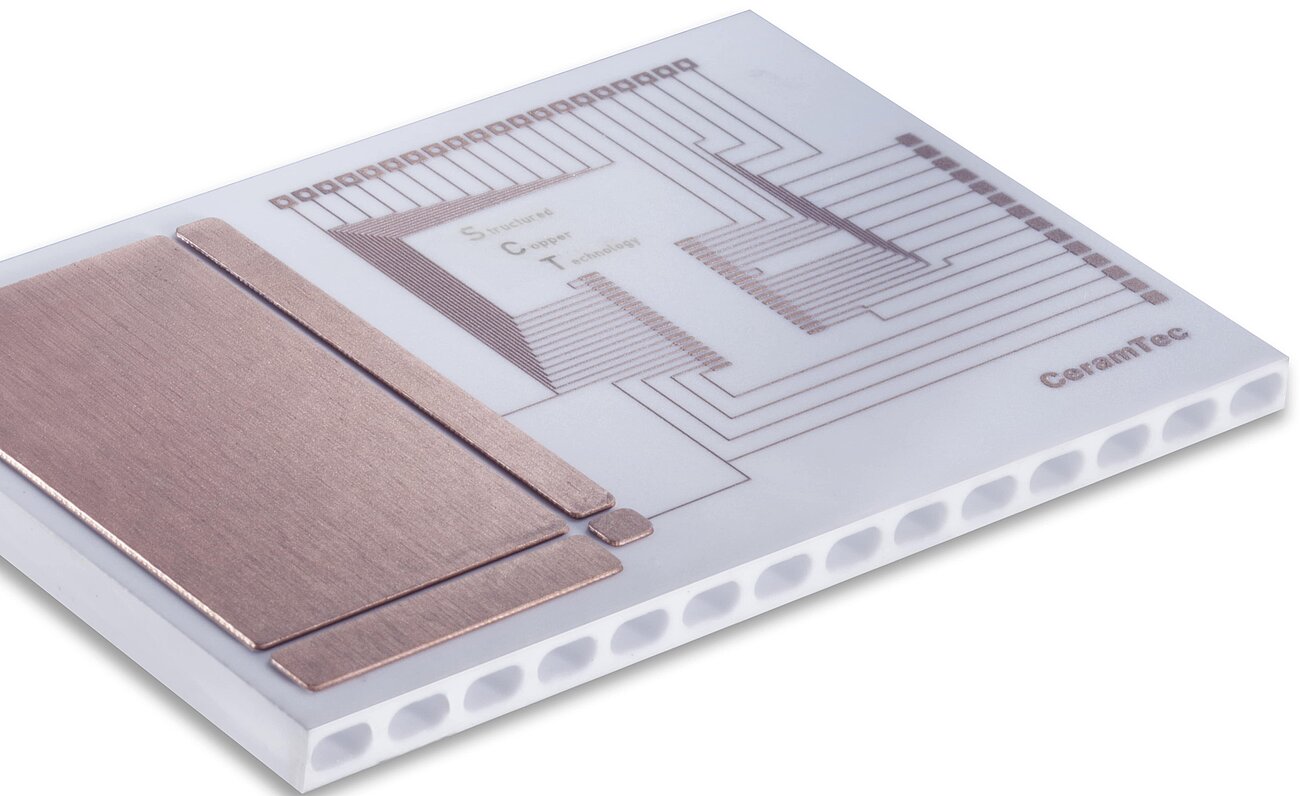

Evaluation and optimization of ceramic heat-sinks with thermal simulation models

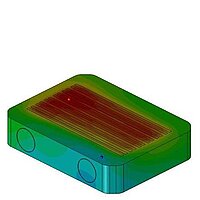

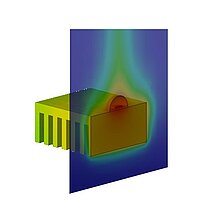

If a CeramCool® heat-sink design is scheduled for prototype or series production, a simulation and analysis of the thermal parameters can be obtained in advance as part of the development process. In this way, the component geometry can be specifically designed for optimum heat dissipation performance in the intended area of application.

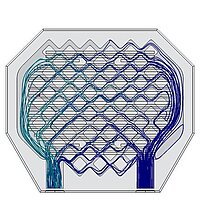

Since most CeramCool® heat-sinks feature customer-specific details, it makes sense to examine the performance of new solutions before manufacturing complex prototypes and optimize as necessary. CeramTec developed suitable simulation models with a reliable correlation to physical tests for this purpose. With these models, new concepts or variations of CeramCool® heat-sinks can be evaluated as early as the development phase, thus enabling unique cooling system solutions tailored specifically to customer needs.

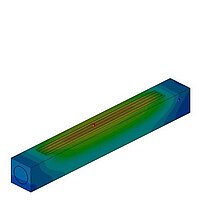

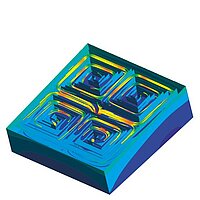

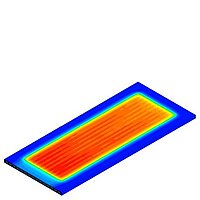

CeramCool® Thermal Simulation

- Optimization of heat-sink design according to customer specifications and application scenarios

- High correlation between simulation models and results of physical tests and prototype measurements